Photovoltaic panels installation system

Freistehende

– dense profile perforation provides a wide adjustment range without drilling

– longitudinal profile perforation allows for smooth adjustment of the inclination angle of the structure –

– possibility of assembling the structure – with only one type of screws – SGKFM10x20

– the perforation of the profiles reduces the weight of the structure – without reducing their strength properties. This means that installers do not have to carry heavy profiles and their work is more efficient.

– dense perforation allows panels to be mounted anywhere without drilling

– if it is not possible to mount the clamp to the profile as standard, there is a possibility to use the UPPMC holder and to grapple on the edge of the profile CMC100H50, which gives a stable fixing of the panel to the structure –

– by using a C-profile, cables can be laid in it safely

– the top perforation of the CWC100H50 profile allows for the installation of both click and standard screw clamps

– longitudinal perforation of support profiles allows for quick installation of brackets and cable trays for safe cable routing and installation of structures for inverters

– possibility to make legs with different sheet thicknesses (3 and 4 mm) depending on the quality of the soil

– production of profiles is carried out on top-class perforating machines, which ensures high quality and repeatability of the products. Profile ends are virtually free of sharp edges, which significantly reduces the possibility of installer’s injuries

– profiles made of sheet metal with Magnelis® coating for long-term corrosion resistance

– products made in Poland!

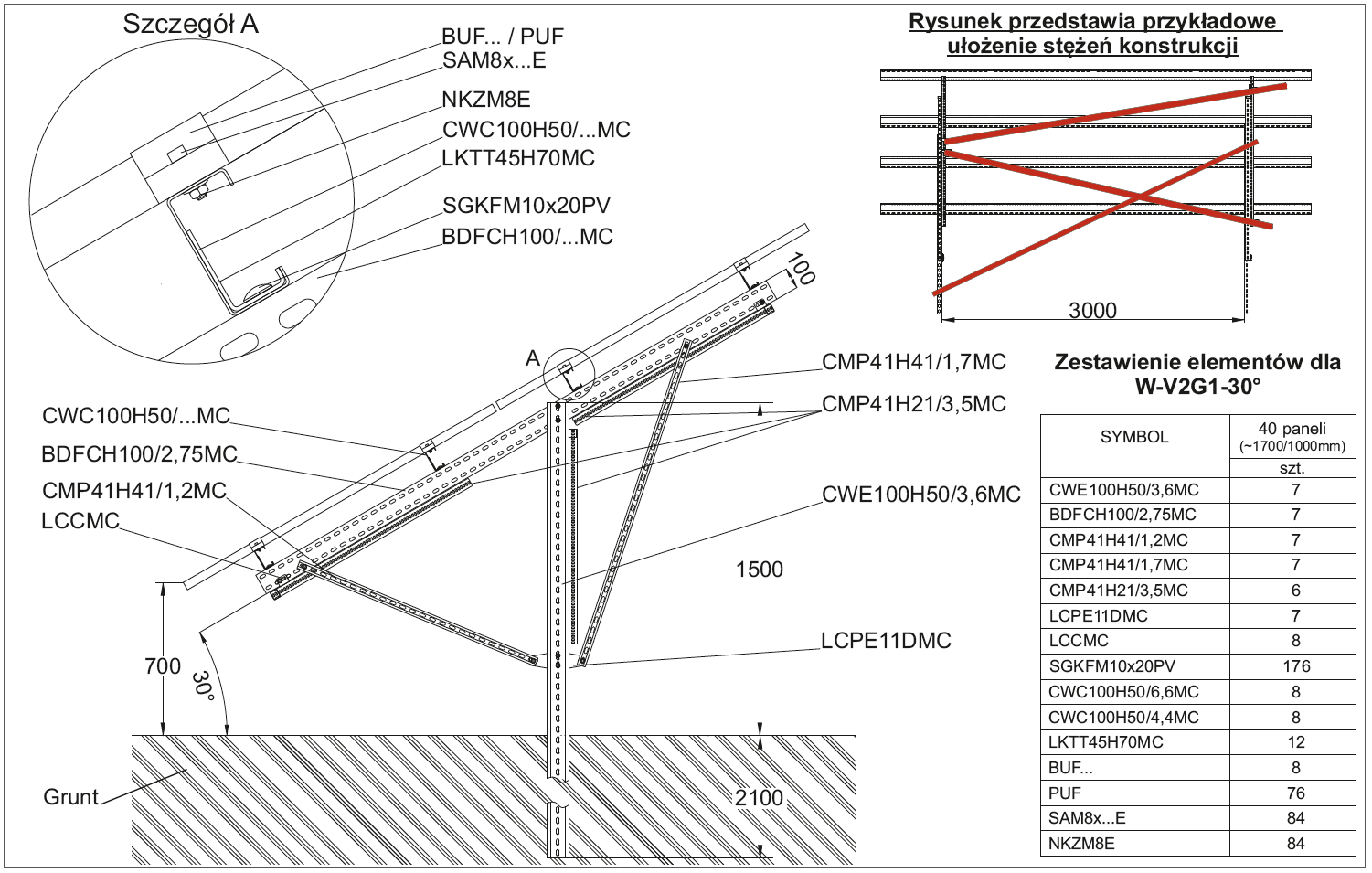

Structure – description:

Complete support system for fixing two rows of panels

in a vertical arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· vertical – V

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-V2G1 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-V2K1 structure – support posts anchored to

the concrete foundation

· W-V2B1 structure – support posts poured with concrete

min. B20 in the holes in the ground (size of

the foundation depends on the ground conditions)

· W-V2S1 structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

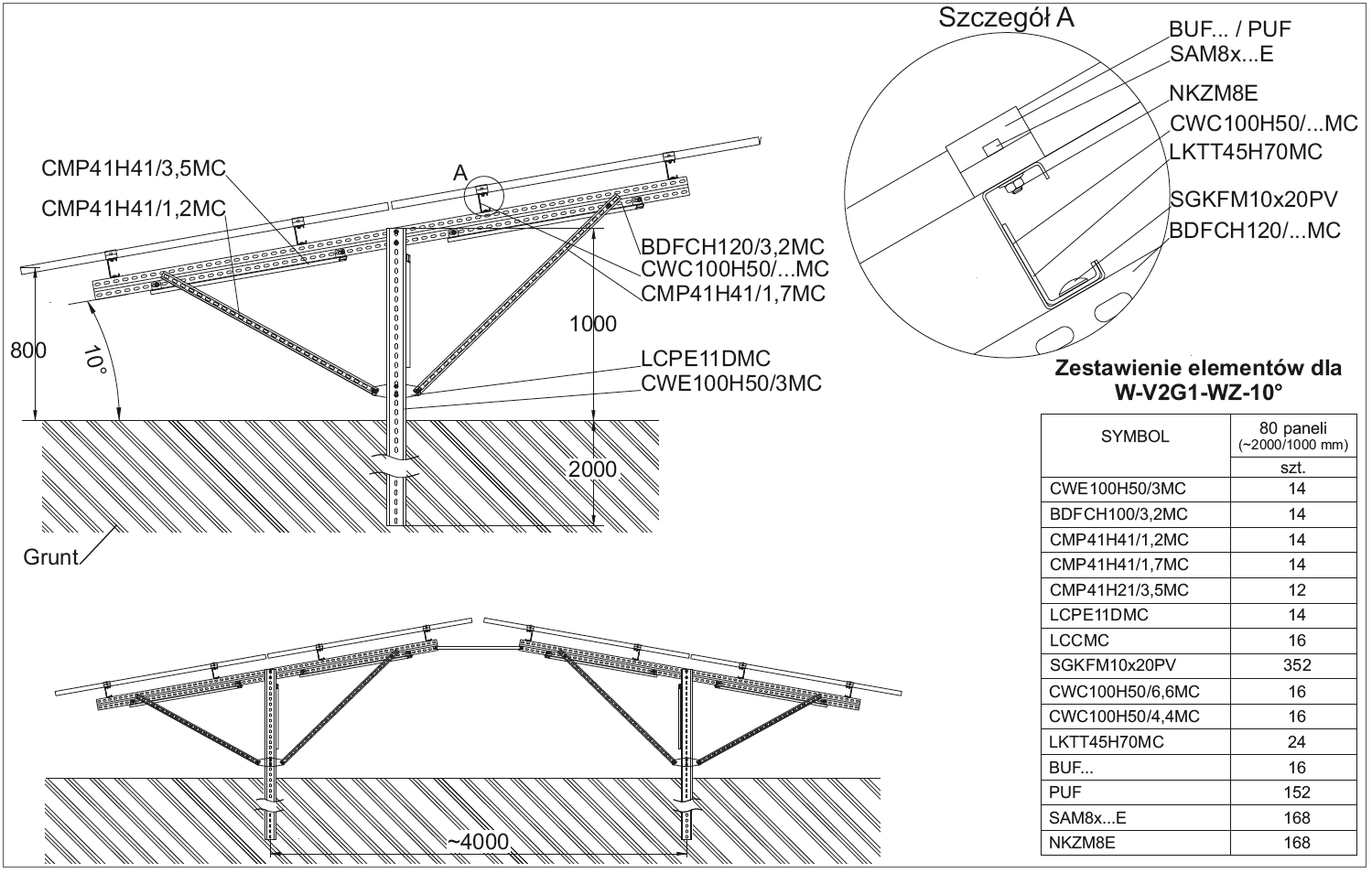

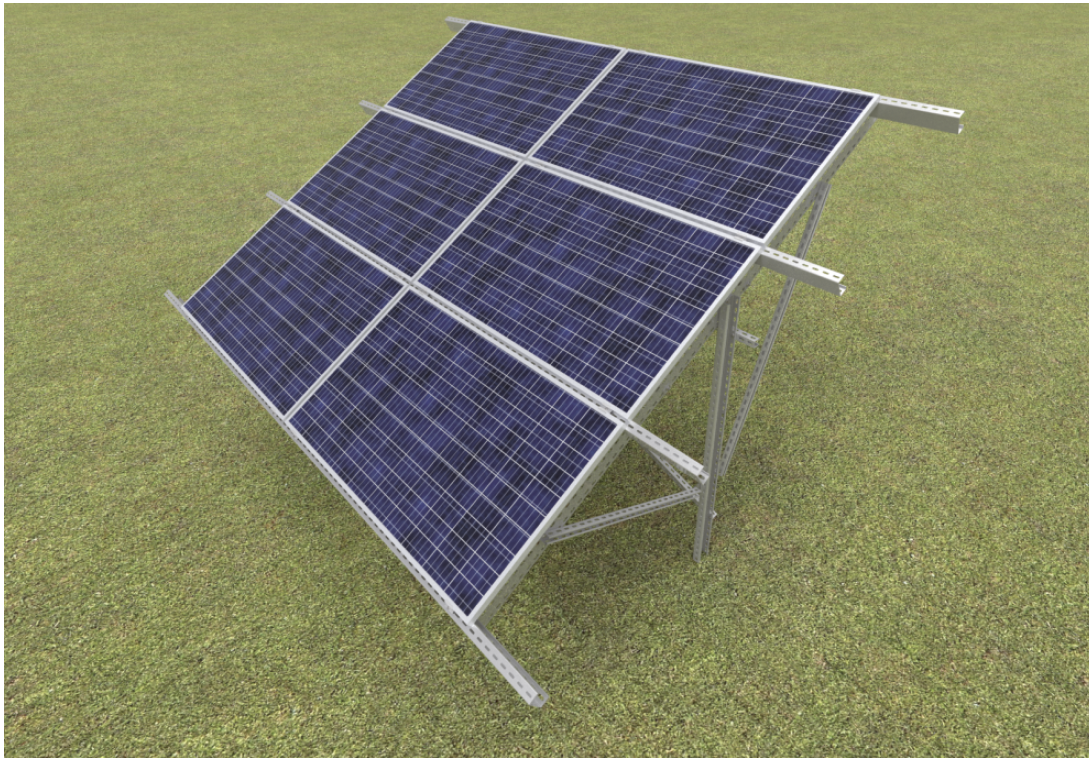

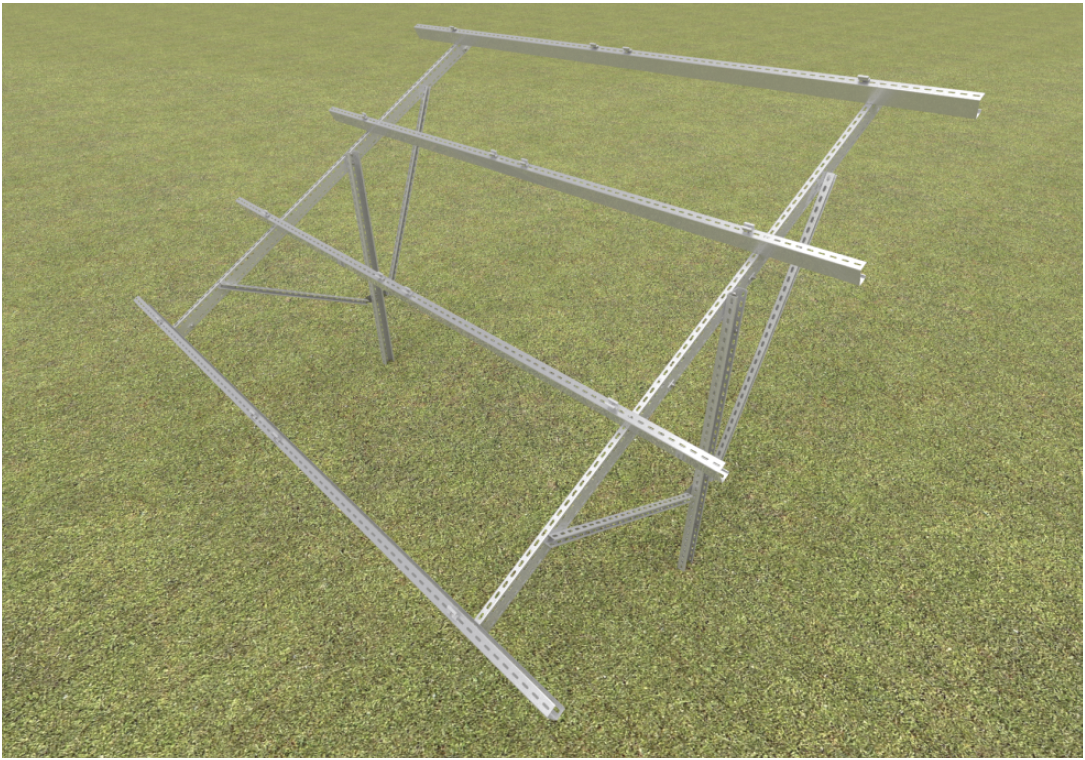

Structure – description:

Complete support system for fixing two rows of panels

in a vertical arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· vertical – V

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-V2G1-WZ structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-V2K1-WZ structure – support posts anchored to

the concrete foundation

· W-V2B1-WZ structure – support posts poured with concrete

min. B20 in the holes in the ground (size of the foundation

depends on the ground conditions)

· W-V2S1-WZ structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

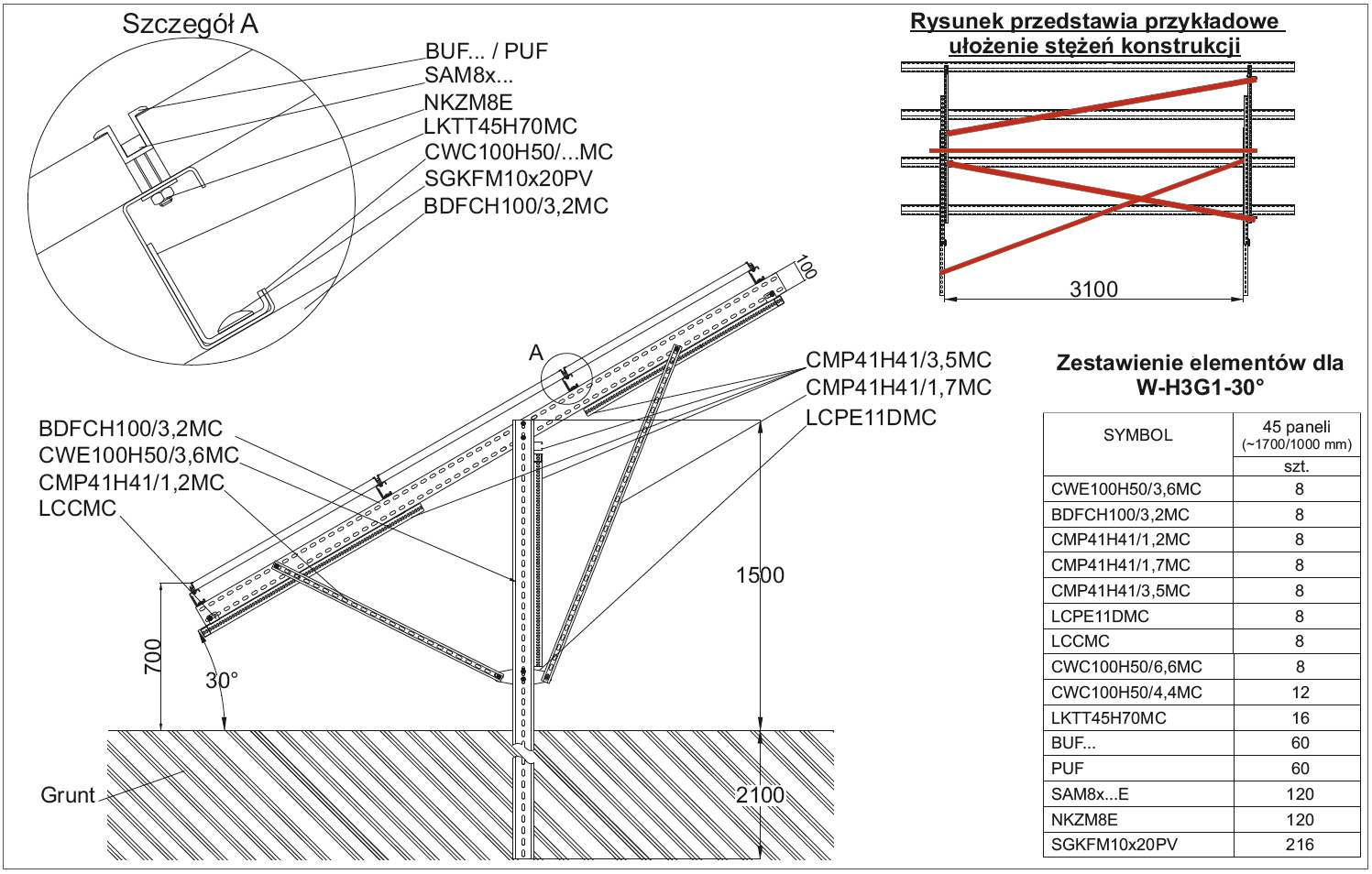

Structure – description:

Complete support system for fixing three rows of panels

in a horizontal arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· horizontal – H

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-H3G1 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-H3K1 structure – support posts anchored to

the concrete foundation

· W-H3B1 structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of

the foundation depends on the ground conditions)

· W-H3S1 structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

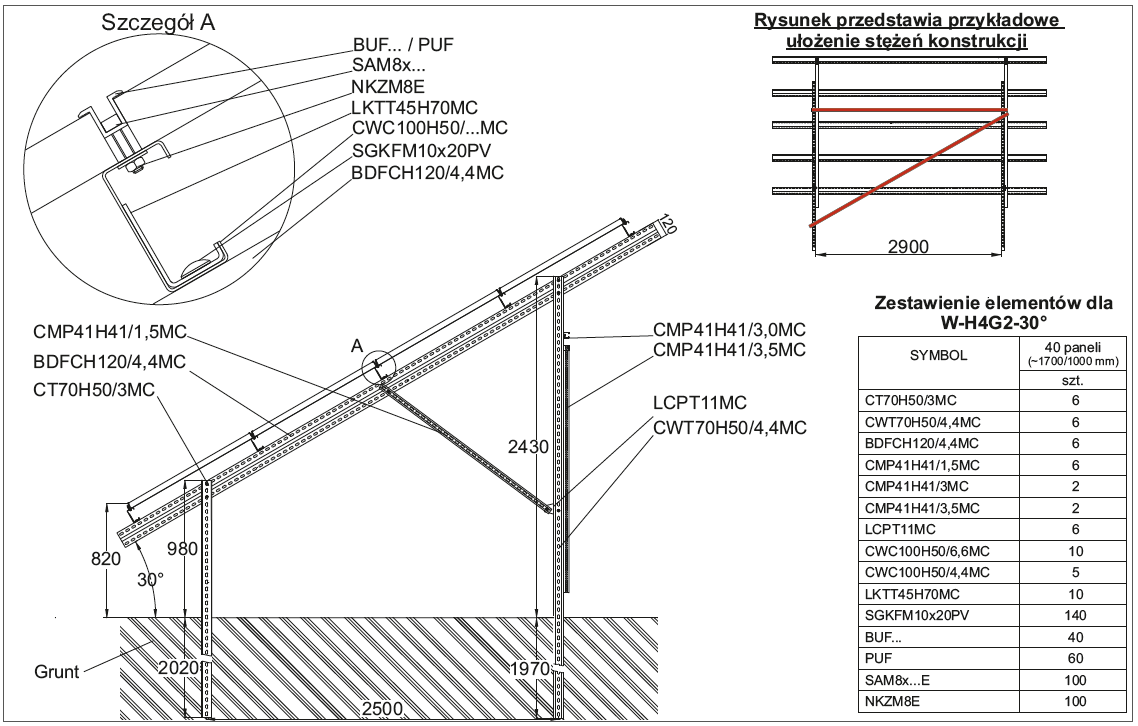

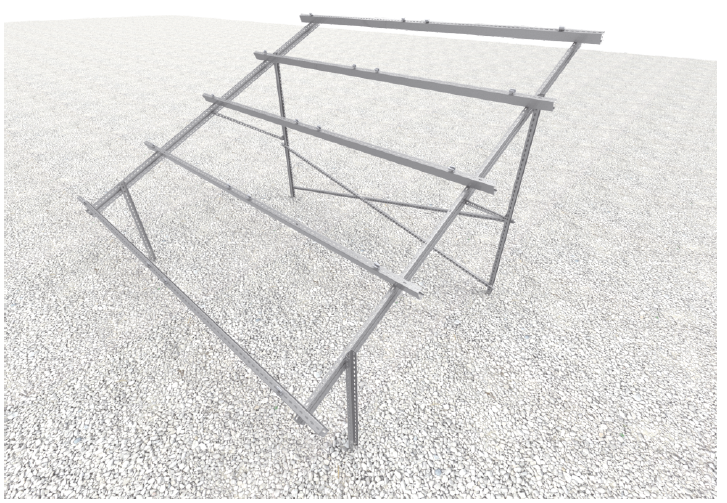

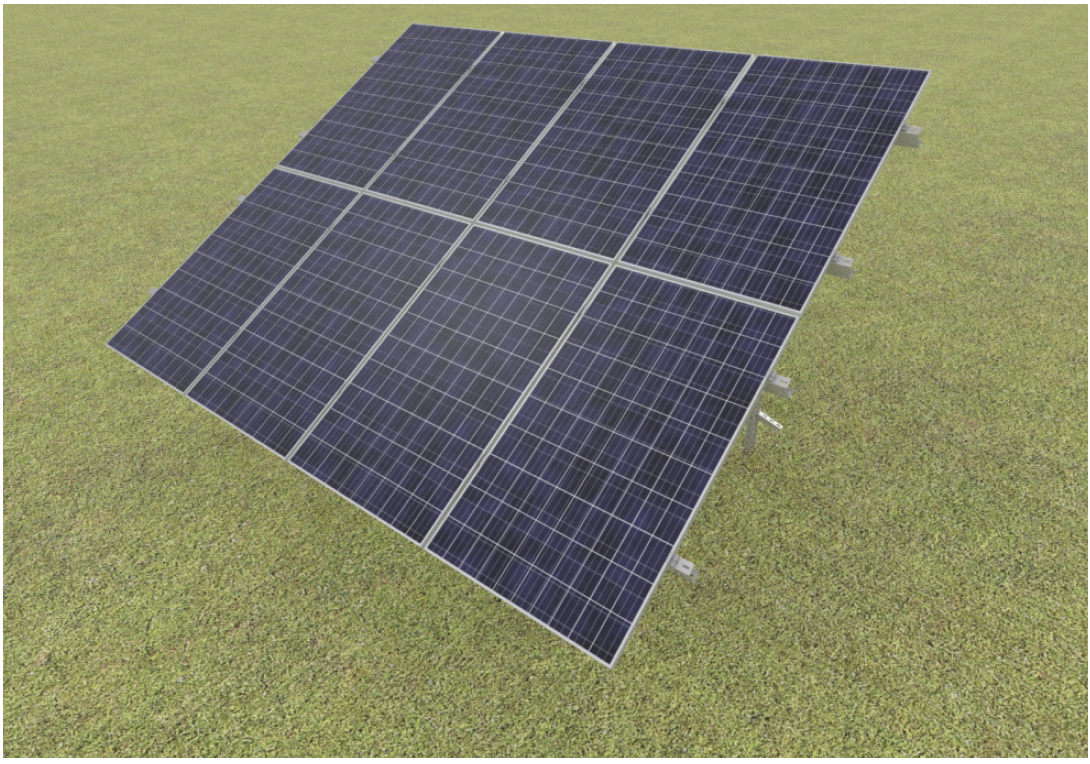

Structure – description:

Complete support system for fixing four rows of panels

in a horizontal arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· horizontal – H

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-H4G2 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-H4K2 structure – support posts anchored to

the concrete foundation

· W-H4B2 structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of the

foundation depends on the ground conditions)

· W-H4S2 structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

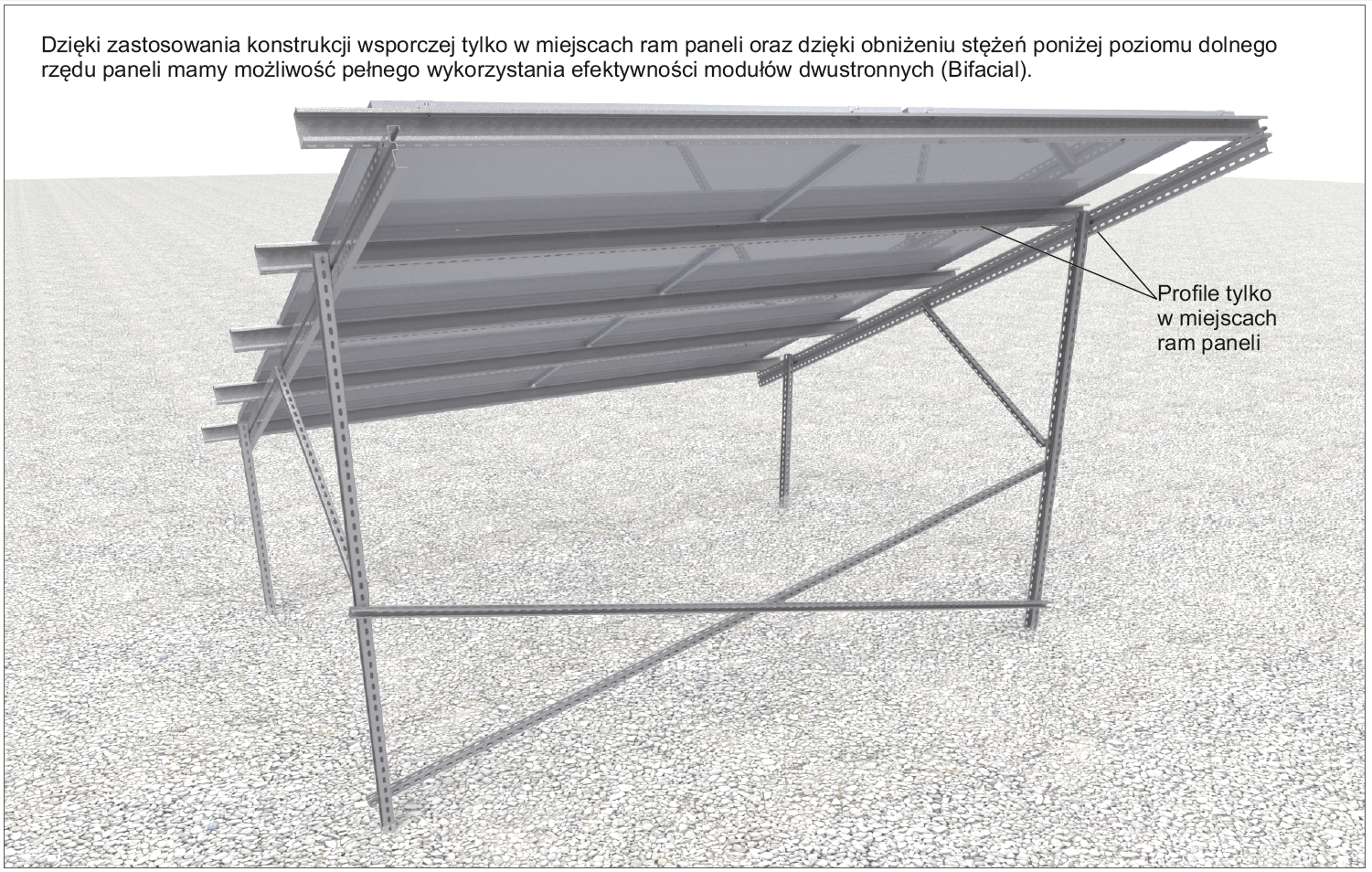

Structure – description:

Complete support system for fixing bifacial panels that use

the sunlight reflected from the ground

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Overview structure

Arrangement of the modules:

· horizontal – H

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-H4G2-BI structure – rammed into the ground

(anchorage depth depending on ground conditions)

· W-H4K2-BI structure – support posts anchored to

the concrete foundation

· W-H4B2-BI structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of the

foundation depends on the ground conditions)

· W-H4S2-BI structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

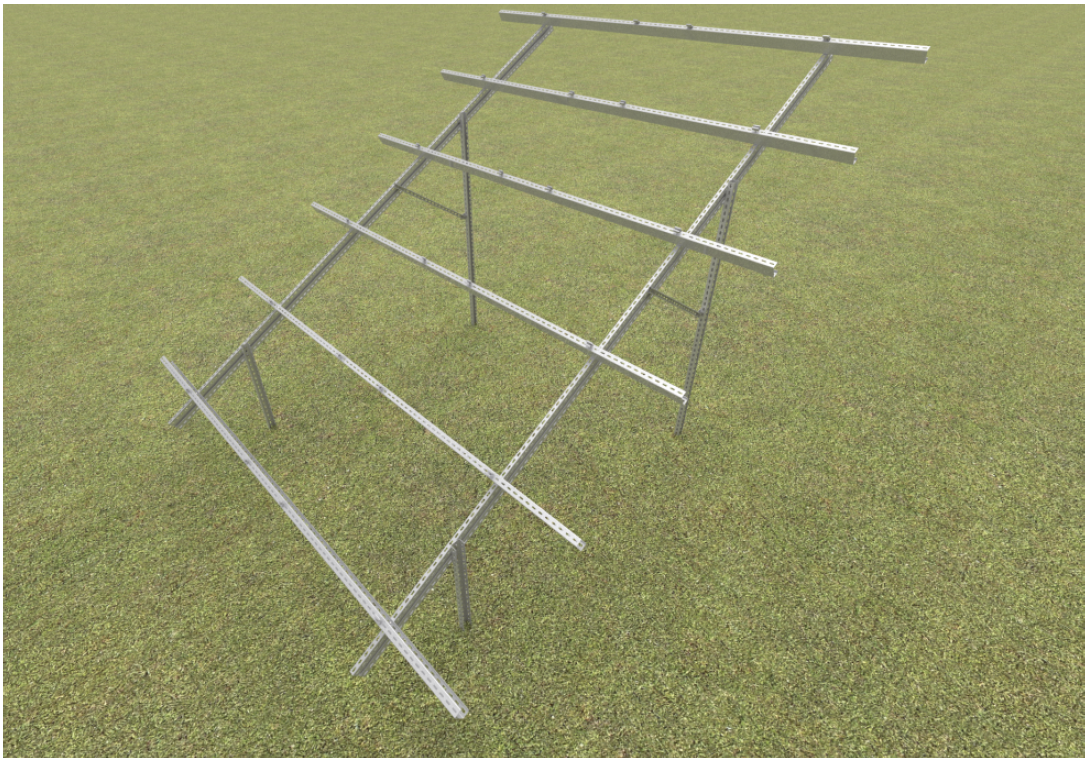

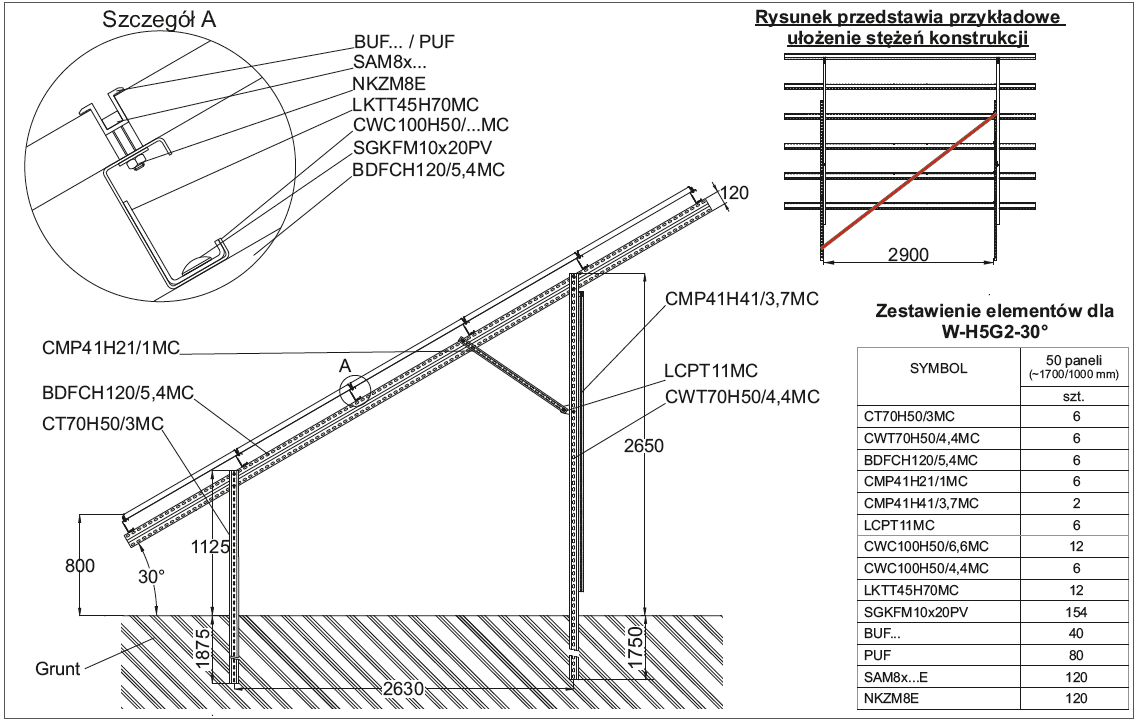

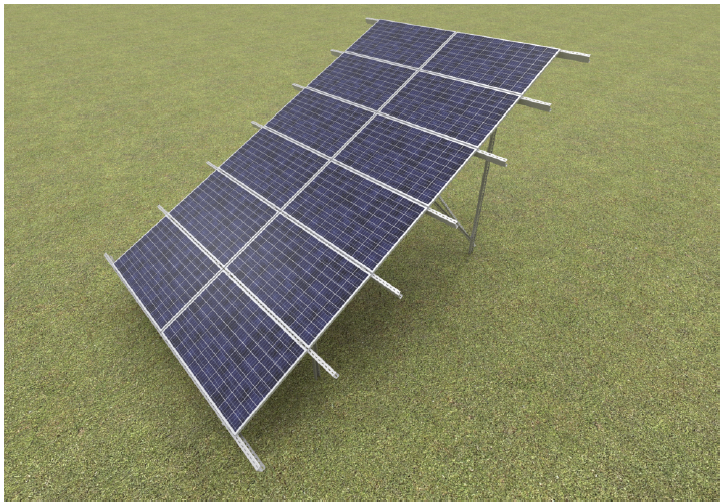

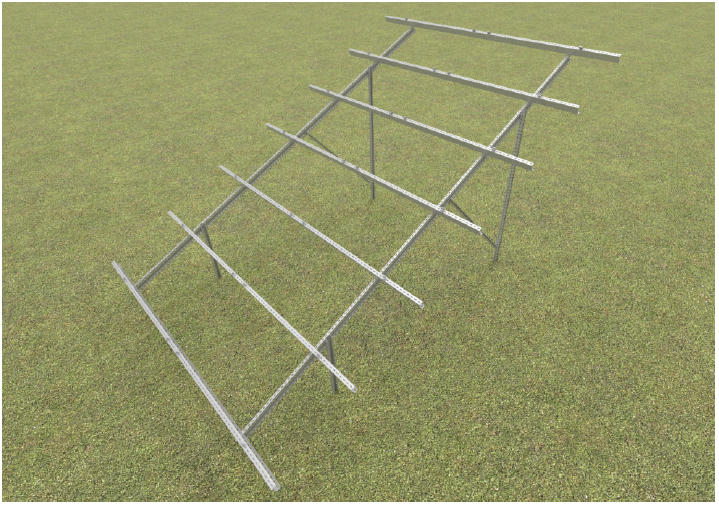

Structure – description:

Complete support system for fixing five rows of panels

in a horizontal arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· horizontal – H

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-H5G2 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-H5K2 structure – support posts anchored to

the concrete foundation

· W-H5B2 structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of the

foundation depends on the ground conditions)

· W-H5S2 structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

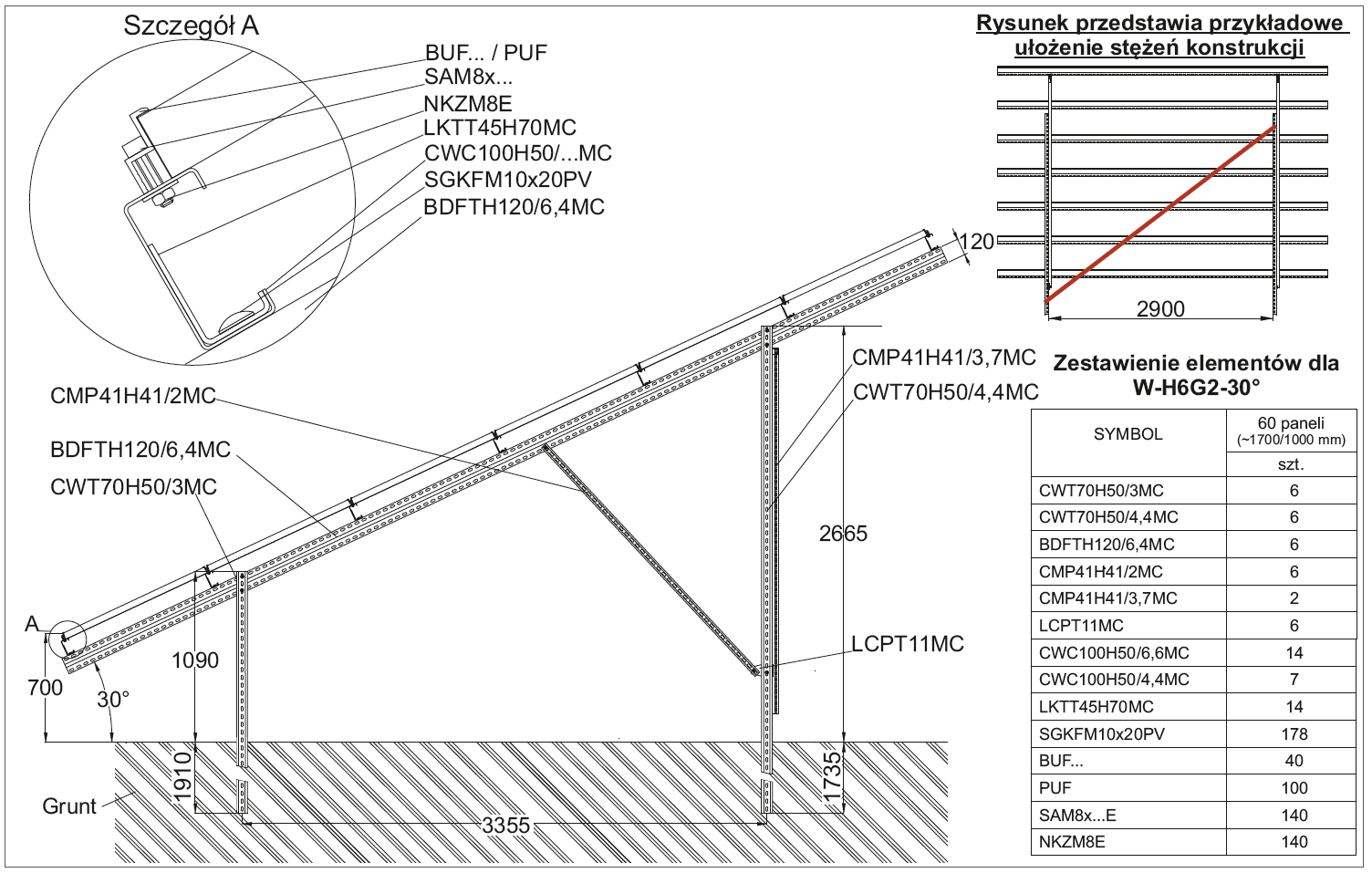

Structure – description:

Complete support system for fixing six rows of panels

in a horizontal arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· horizontal – H

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-H6G2 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-H6K2 structure – support posts anchored to

the concrete foundation

· W-H6B2 structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of the

foundation depends on the ground conditions)

· W-H6S2 structure – on request, a screw screwed into

the ground for fixing of the support posts

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

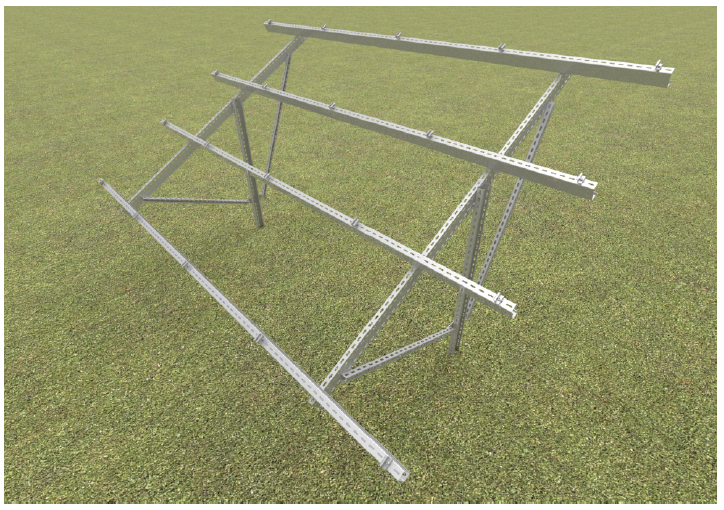

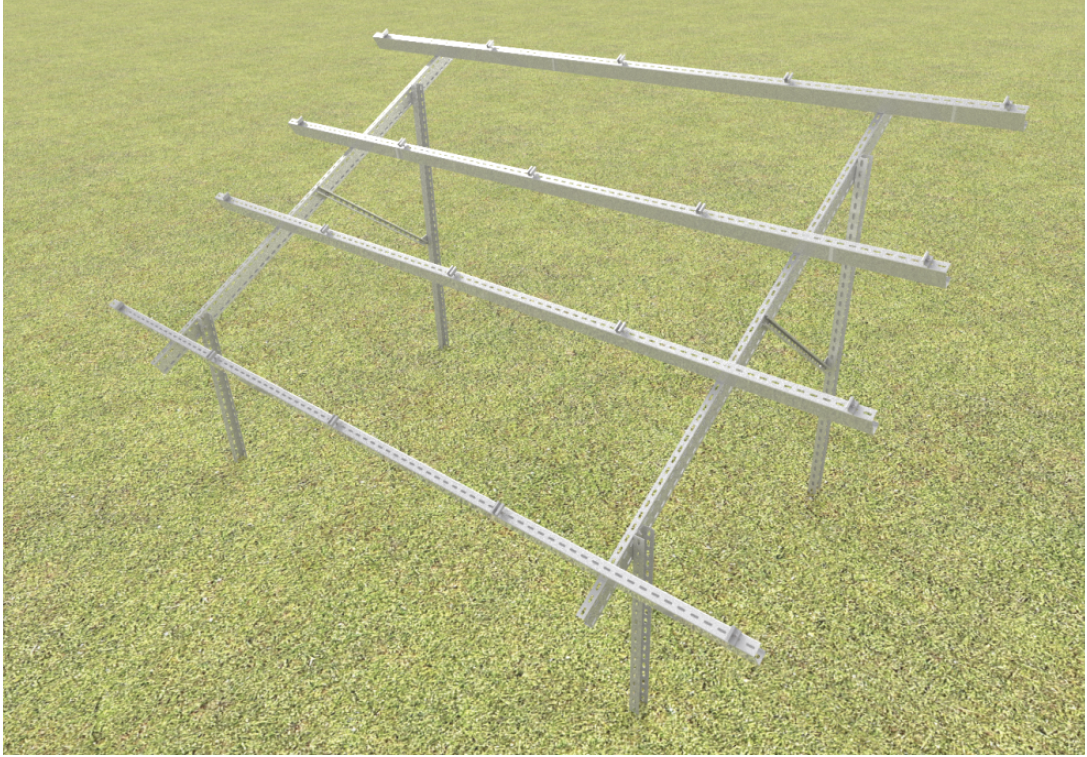

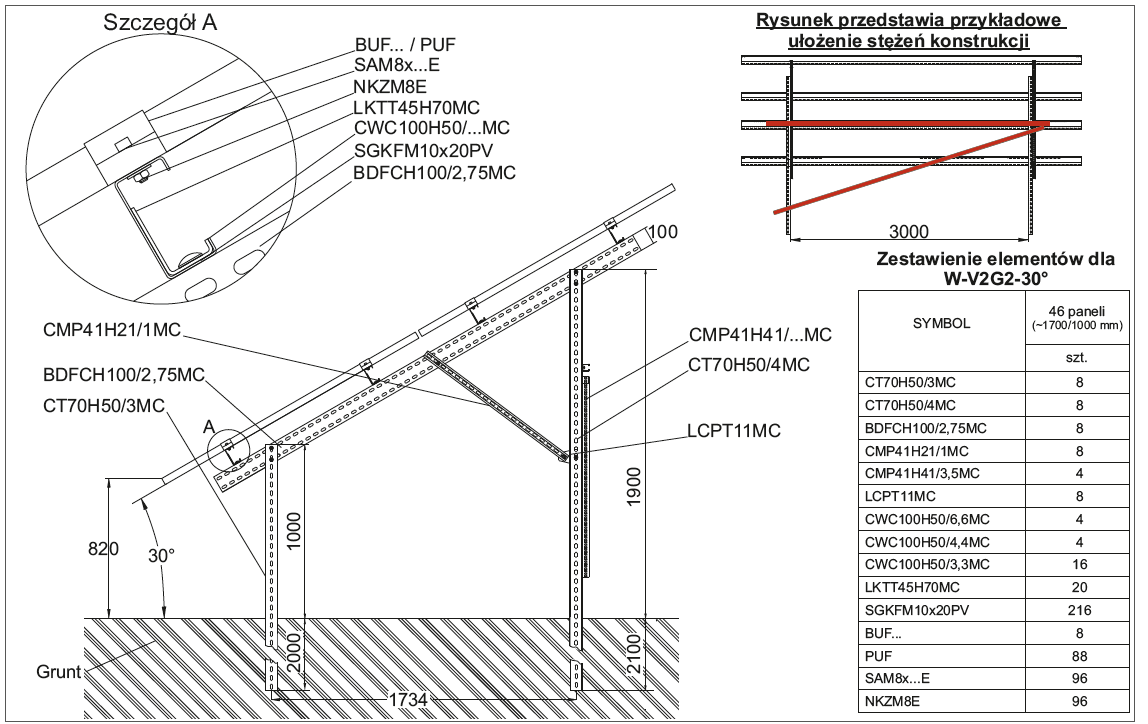

Structure – description:

Complete support system for fixing two rows of panels

in a vertical arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· vertical – V

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-V2G2 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-V2K2 structure – support posts anchored to

the concrete foundation

· W-V2B2 structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of the

foundation depends on the ground conditions)

· W-V2S2 structure – on request, a screw screwed into

the ground for fixing of the support post

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

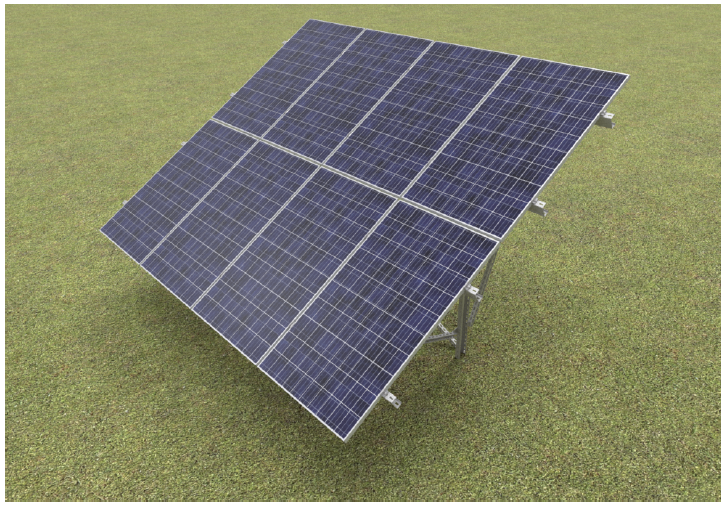

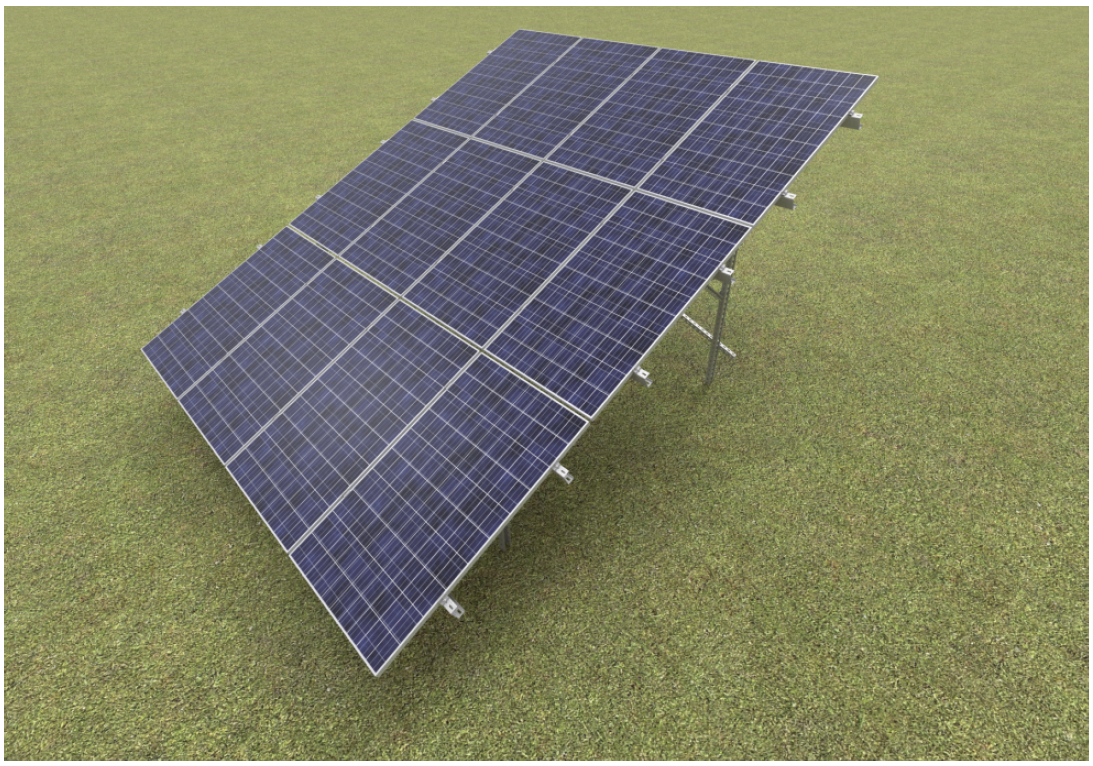

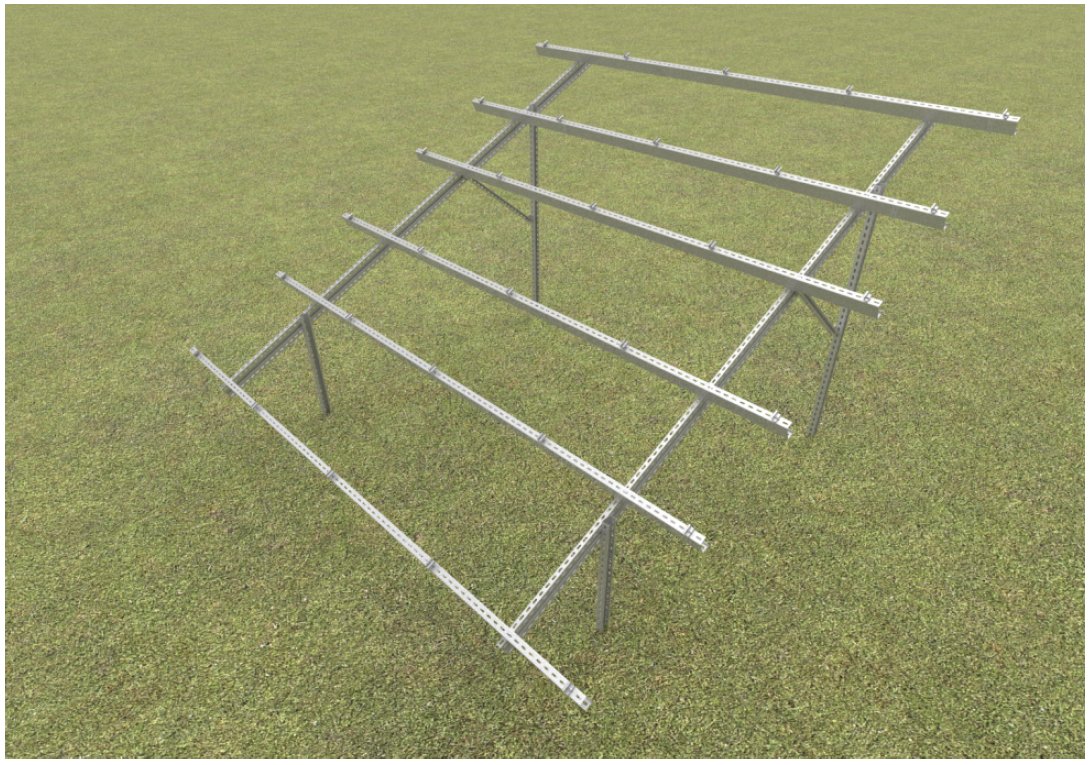

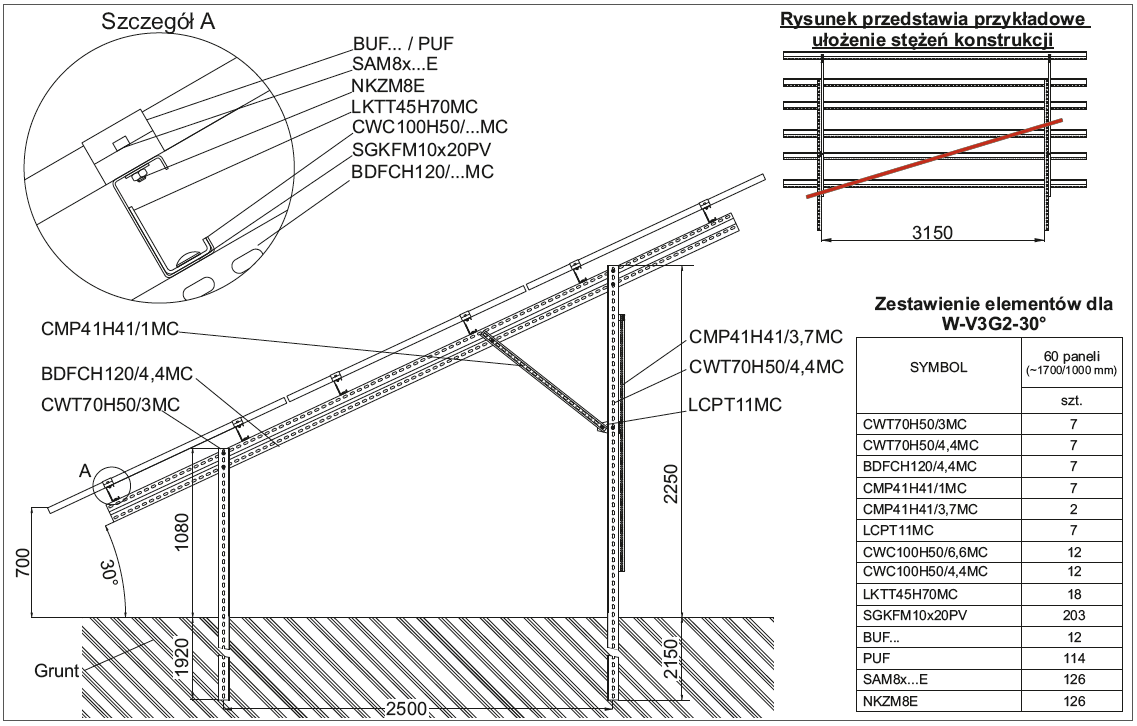

Structure – description:

Complete support system for fixing three rows of panels

in a vertical arrangement

Technical description:

Materials of the support system:

MC- constructional steel in grades S250GD and S350GD in

Magnelis® coating, ZM430 for support posts, ZM310 for

assembled parts above ground

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure – tested for strength

Arrangement of the modules:

· vertical – V

Ground conditions:

· soil with good/high load capacity

Construction assembly variants:

· W-V3G2 structure – rammed into the ground

(anchorage depth depends on ground conditions)

· W-V3K2 structure – support posts anchored to

the concrete foundation

· W-V3B2 structure – support posts poured with concrete

min. B20 in the holes made in the ground (size of the

foundation depends on the ground conditions)

· W-V3S2 structure – on request, a screw screwed into

the ground for fixing of the support post

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure – only if all conditions of the

manufacturer’s warranty are met.

The warranty can be extended.

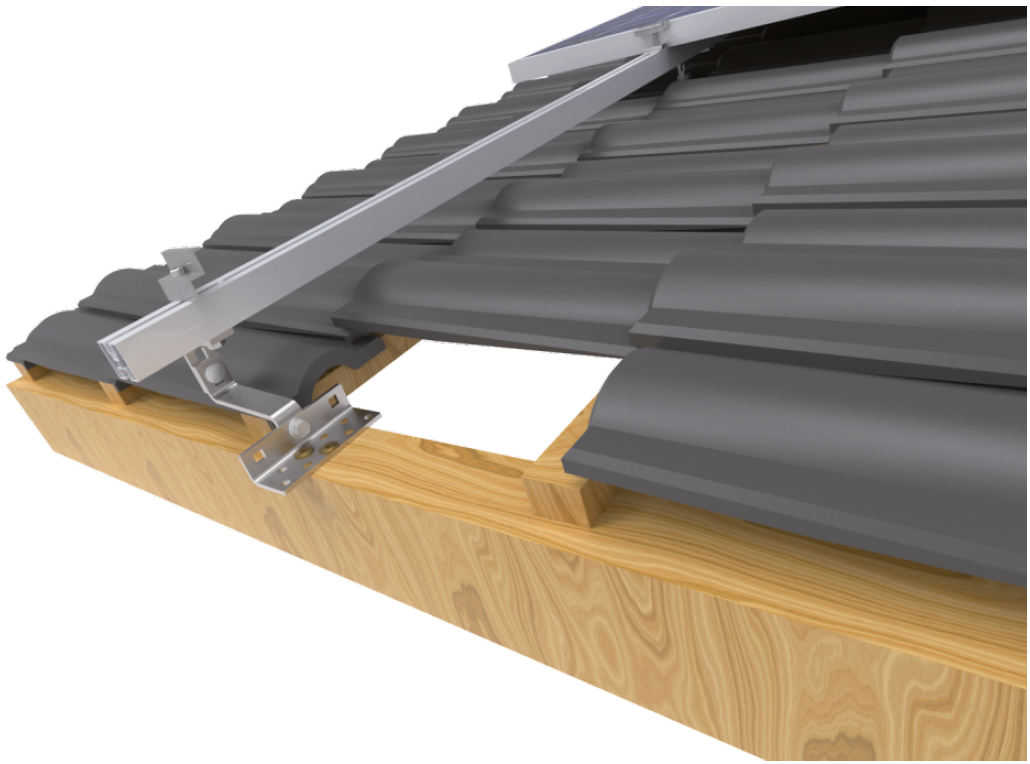

Für Steildächer

– variable adjustment and longitudinal profile perforation allows for trouble-free and quick installation of the structure even in case of unevenness on the roof

– specially profiled holders provide a stable and strong connection to the roof structure or plating

– all structure elements made of stainless steel are subjected to abrasive treatment, which guarantees an aesthetic appearance

– the structure elements are ready for use after taking them out of the packaging and do not require additional completion

– products made in Poland

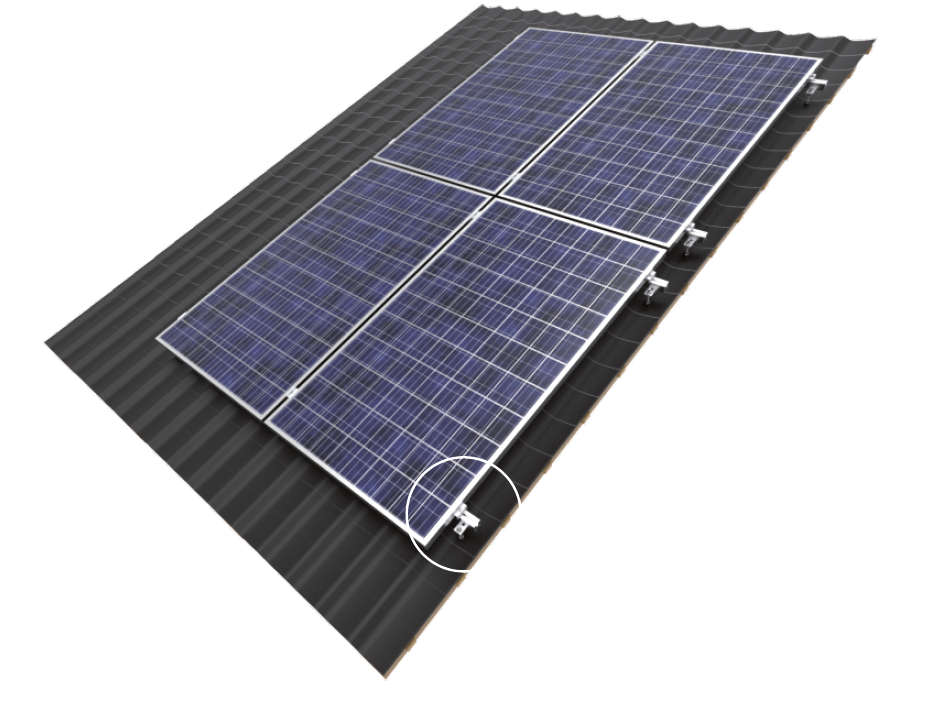

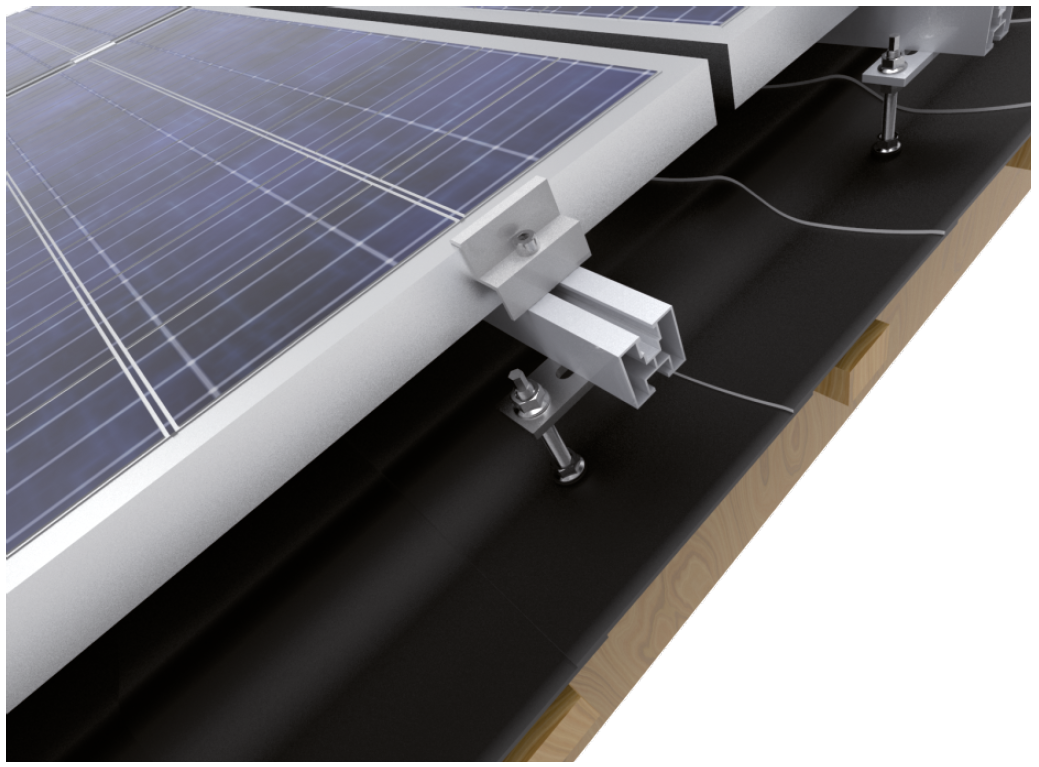

Structure description

Complete support system for any number of PV panels in a

vertical arrangement on a sloping roof covered with metal

tiles sheets or corrugated metal sheets

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Installation of double-threaded screws for roof rafters.

Recommended spacing between screws 0,8 – 1 m.

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– wide range of height adjustment of aluminium profiles in

relation to the roof thanks to the long, threaded part of

the screw

– additional adjustment of the aluminium profiles thanks

to the longitudinal hole in the AD…E adapter

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

– double-threaded screws fitted with rubber to ensure basic

sealing of the hole in the roof tiles

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

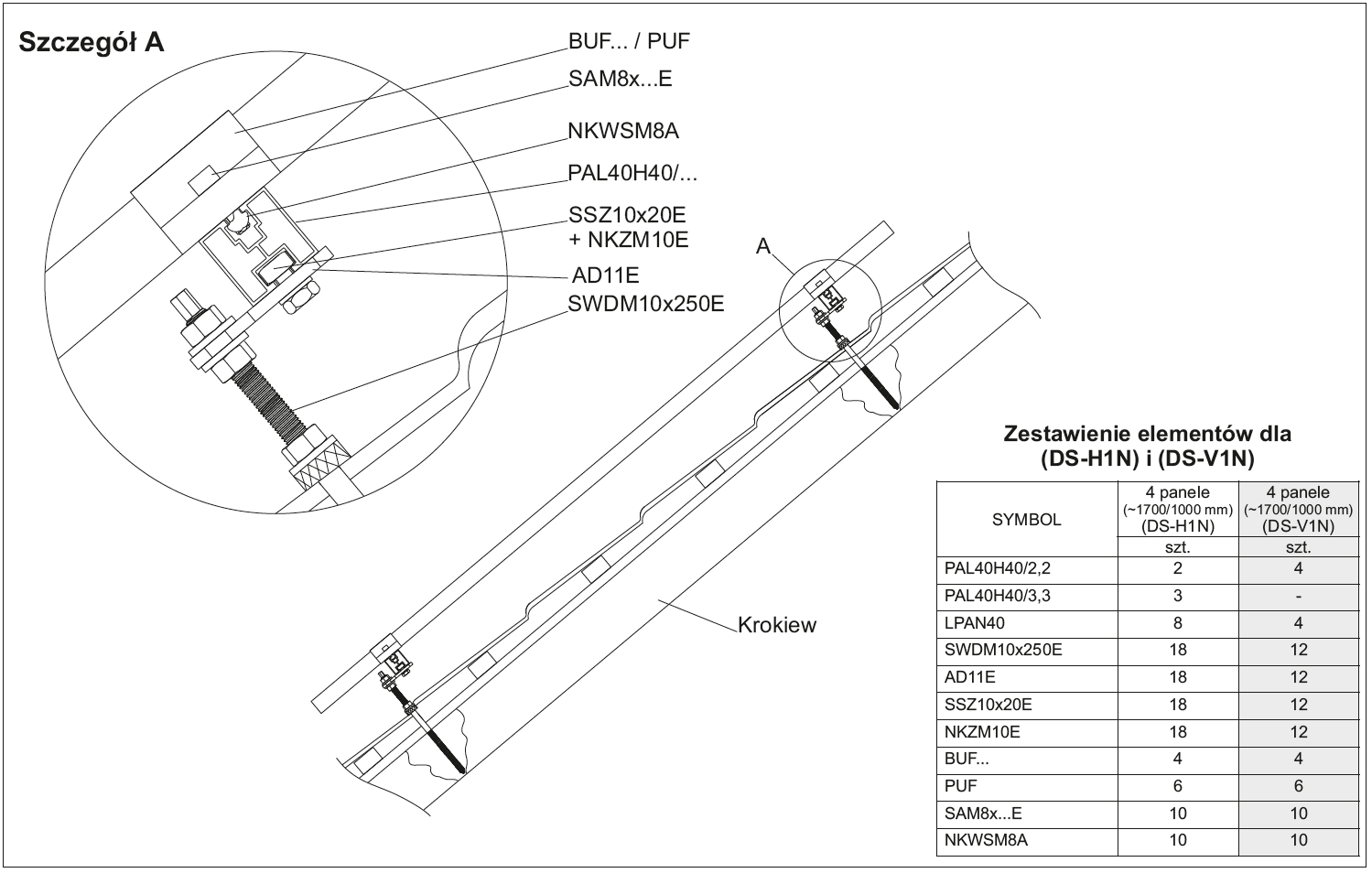

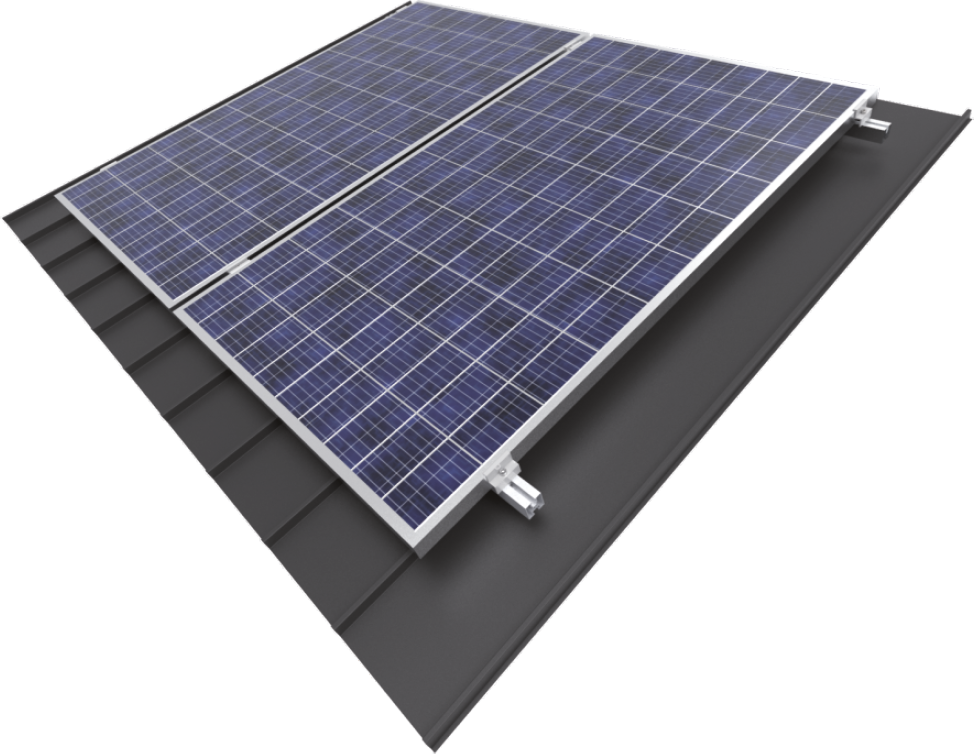

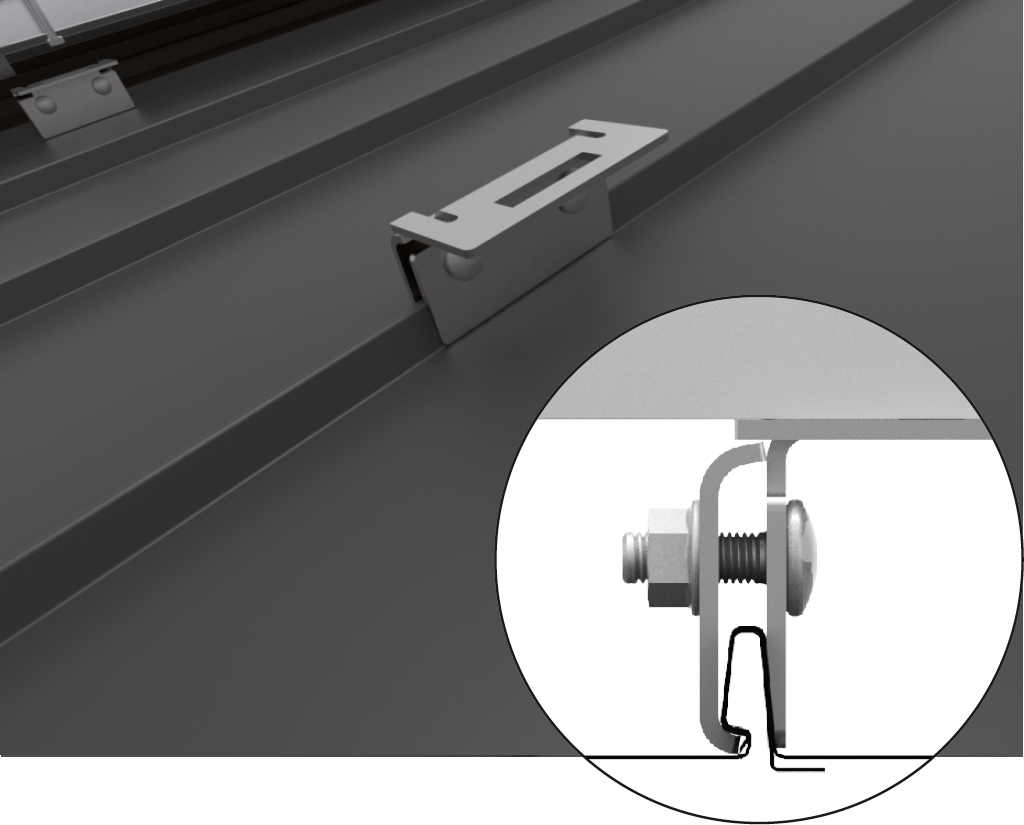

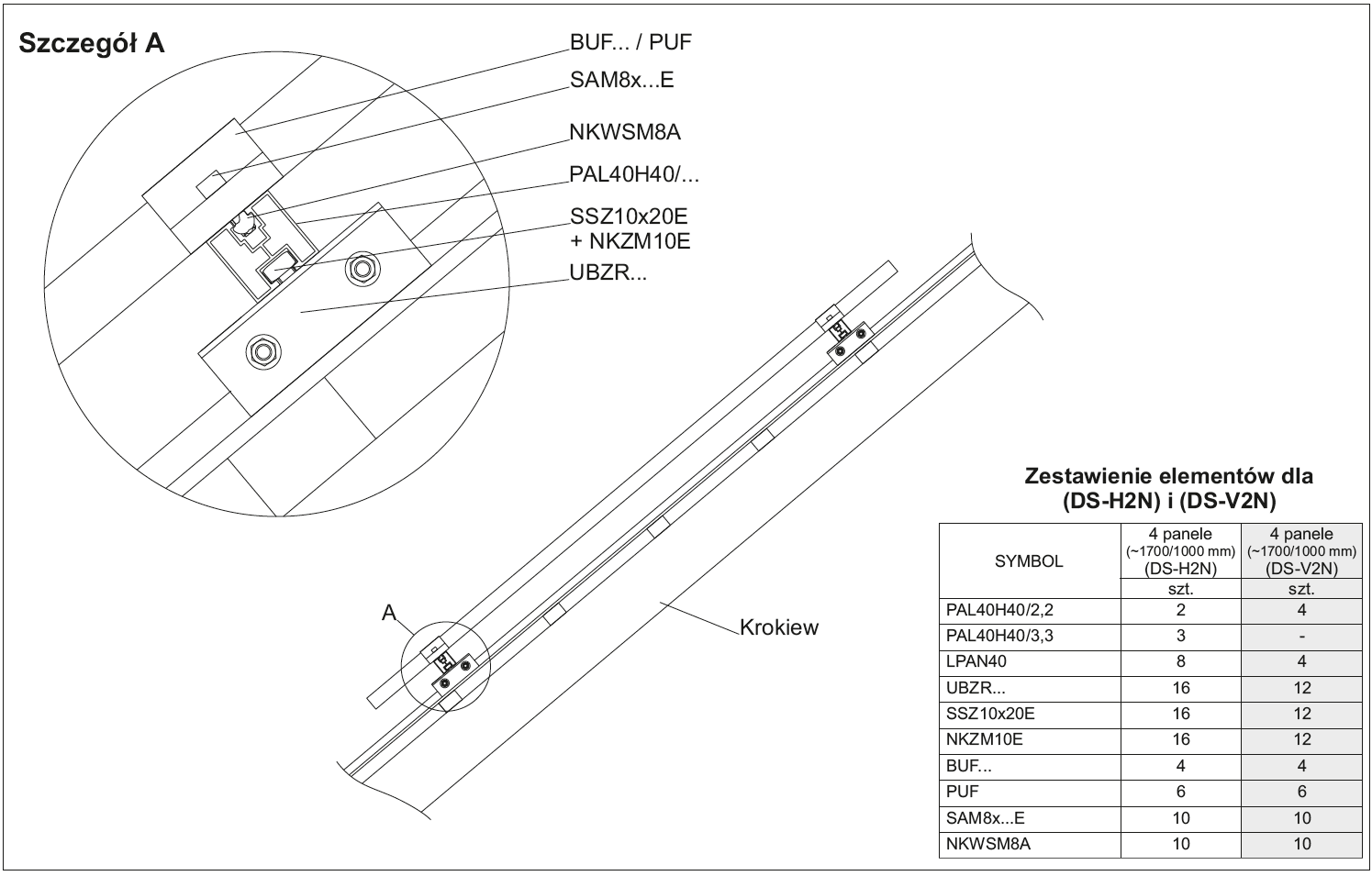

Structure description

Complete support system for any number of PV panels in

a vertical arrangement on a sloping roof covered with sheets

metal seam plates

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

The holders should be mounted to the first three seams, counted

from the edge of each row of panels and then every second seam.

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– installation of the structure to the seam without interfering

with the structure of the roof plating

– quick installation of the holders without the need to locate

the rafters

– different versions of holders for sheets metal to ensure stable

installation with most sheets metal seam plates systems

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

Structure description

Complete support system for any number of PV panels in

a vertical arrangement on a sloping roof covered with

bituminous tiles

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Installation of screws for roof rafters.

Recommended spacing between holders 0.8 – 1 m.

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– the shape of the holders ensures high stability of the structure

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

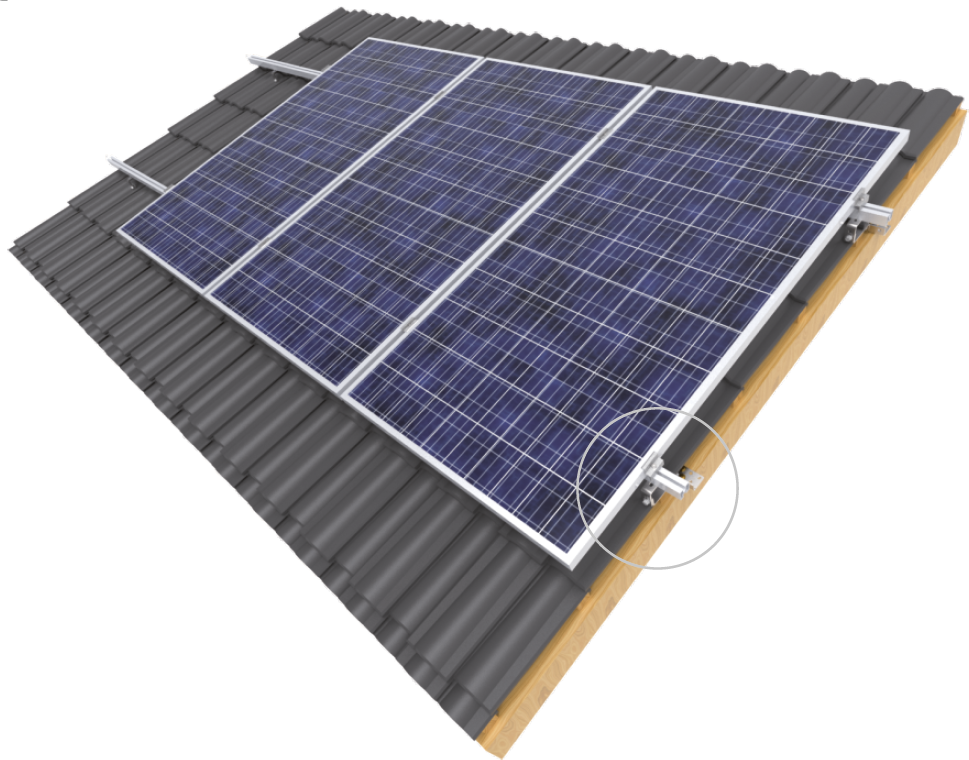

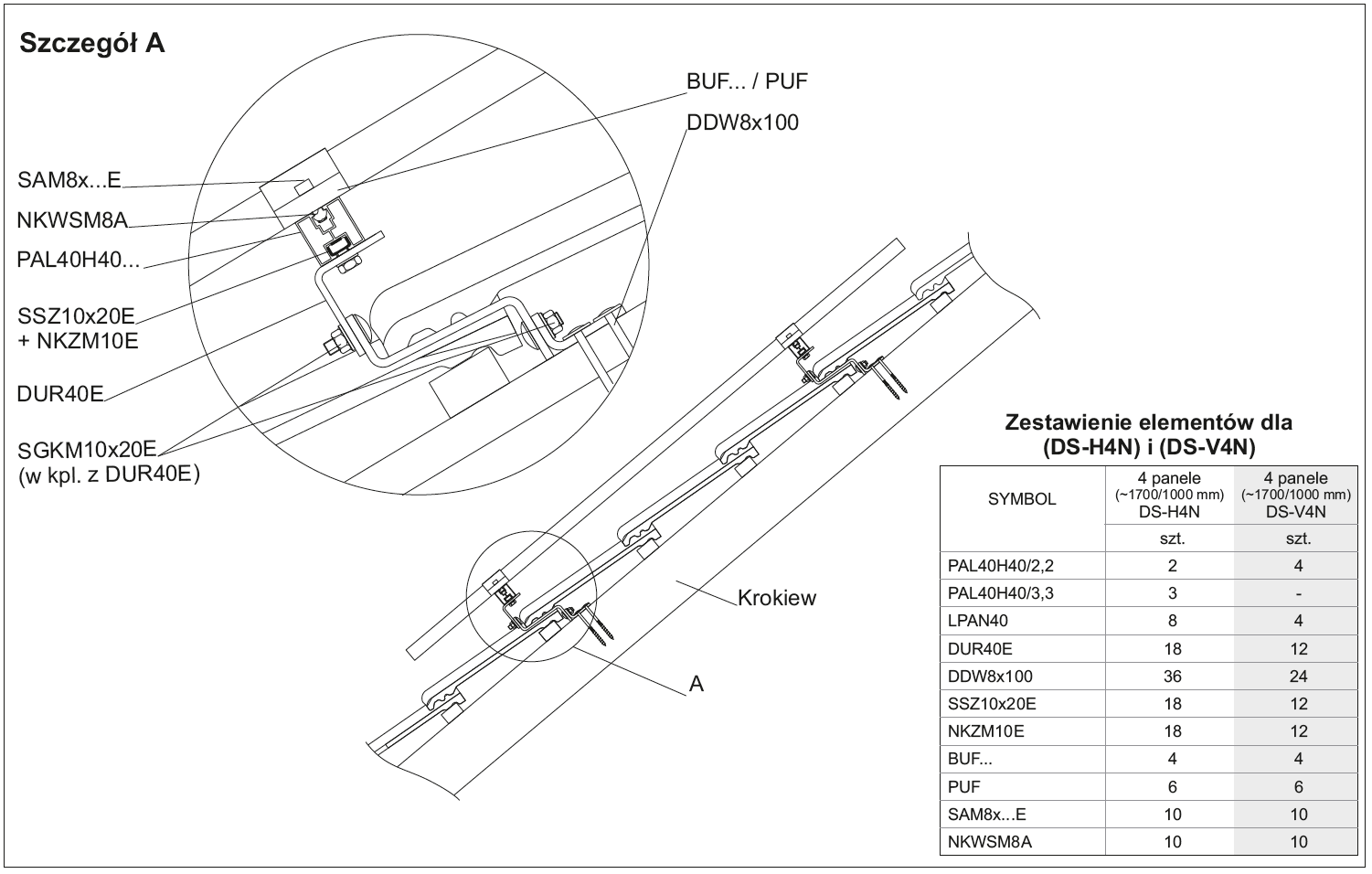

Structure description

Complete support system for any number of PV panels in

a vertical arrangement on a sloping roof covered with

ceramic tiles

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Installation of holders with screws for roof rafters.

Recommended spacing between holders 0.8 – 1 m

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– wide adjustment range of the holders thanks to longitudinal

holes in each of the 3 elements of the holder

– dense holes in the part directly adjacent to the roof truss

ensure that the holder can be adjusted and correctly

positioned in relation to the tiles so that the hook is in the

middle of the tiles mounted below

– elongated middle arm of the holder allows the hooks to be

mounted on the majority of ceramic and concrete roof tiles

available on the market

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

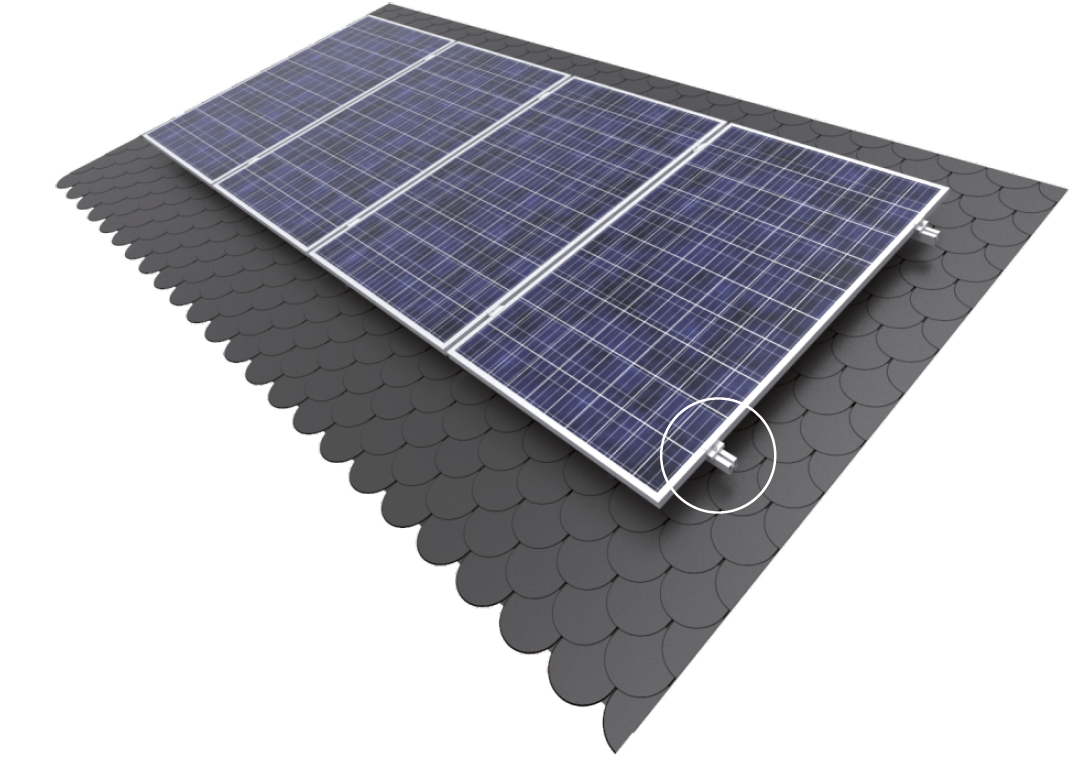

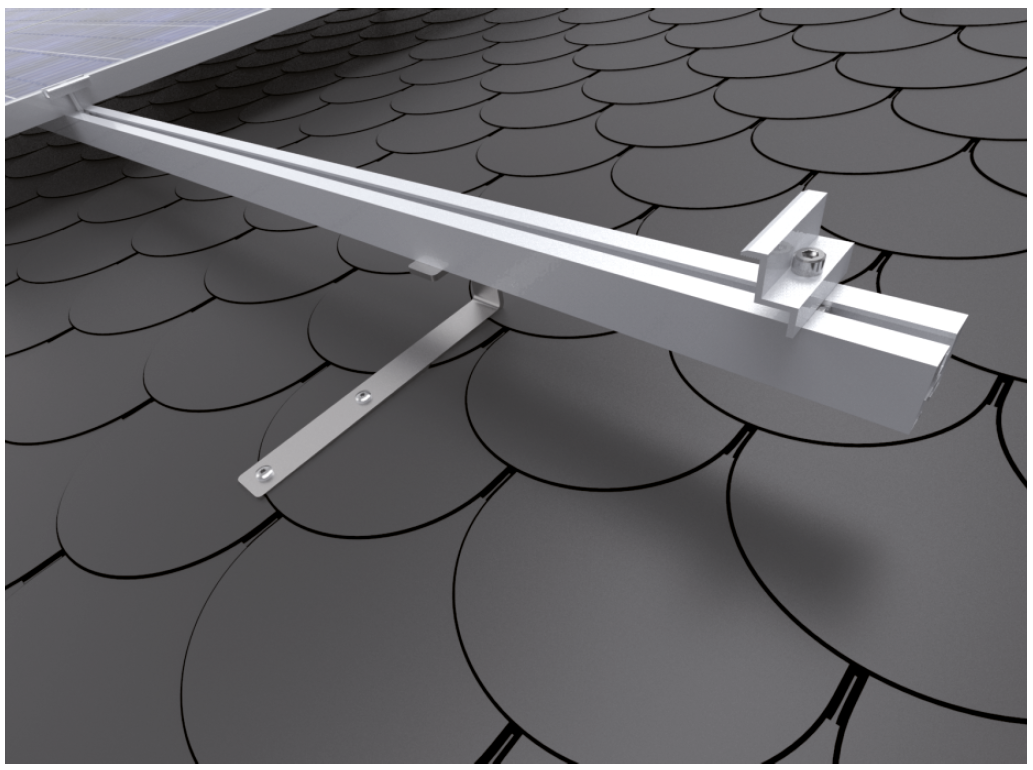

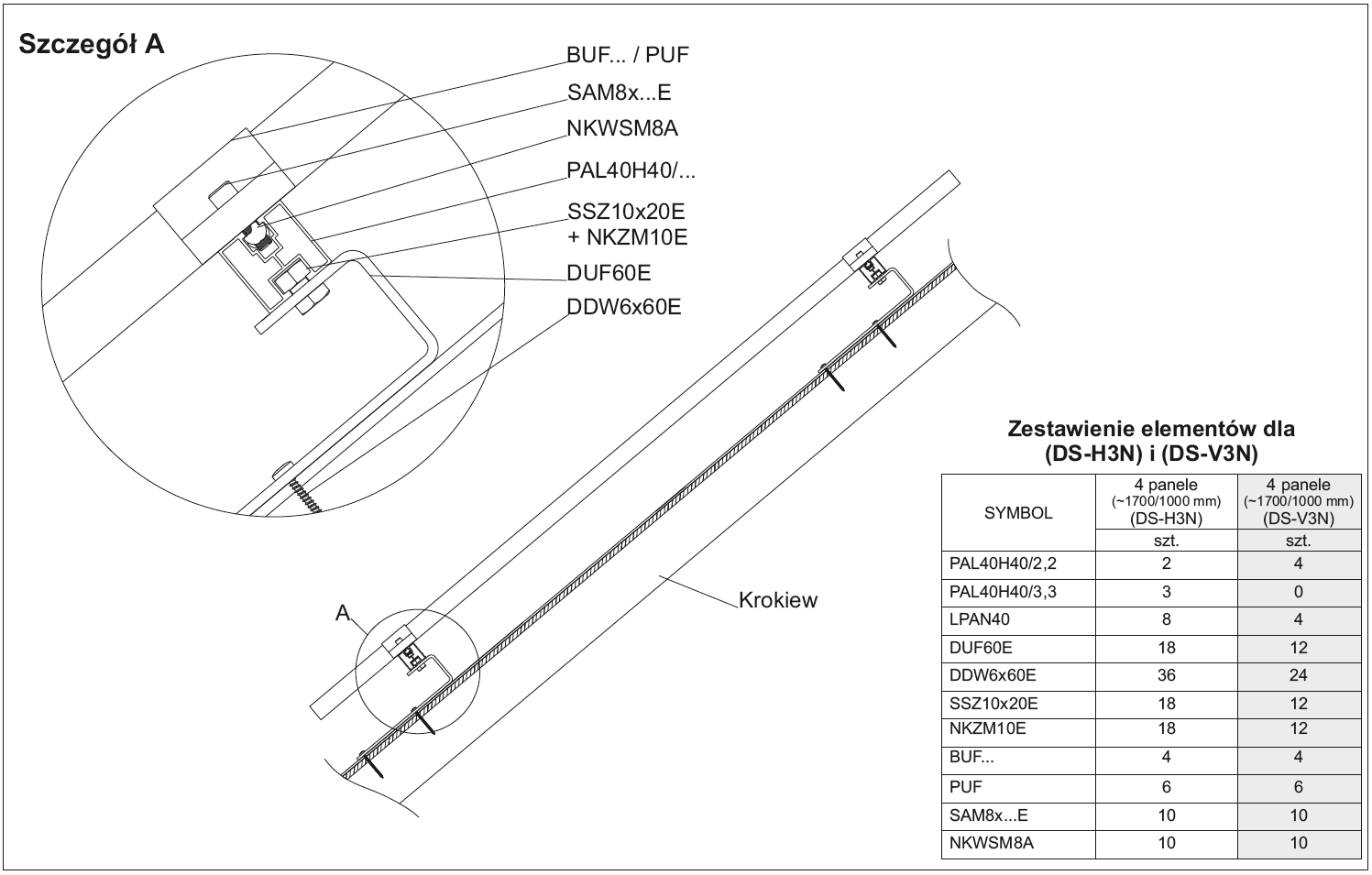

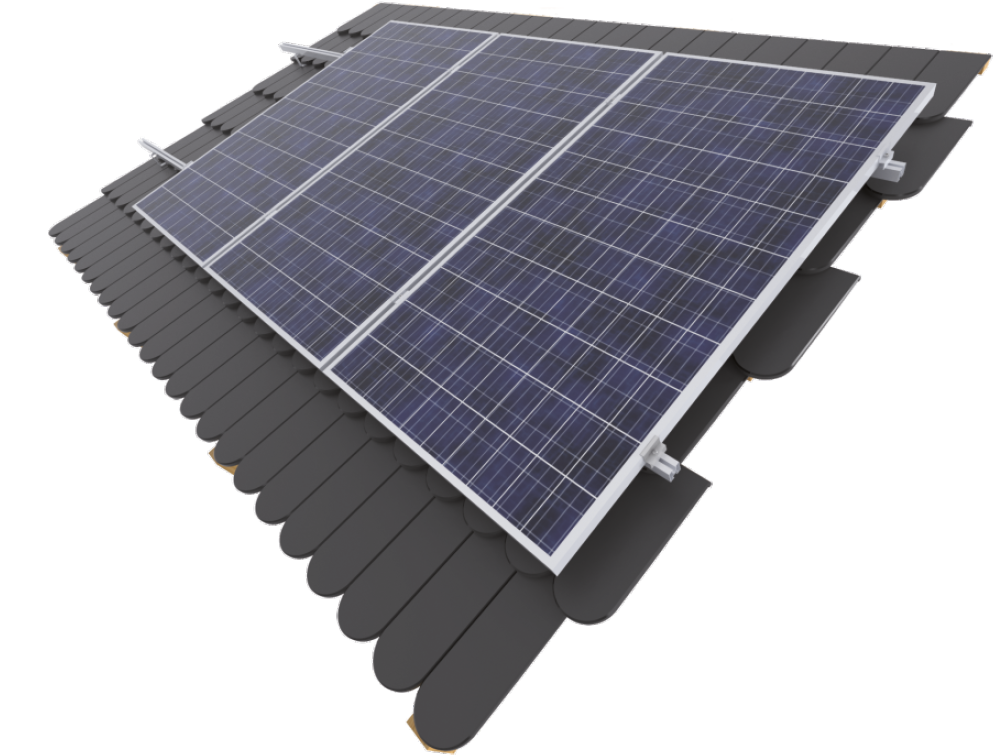

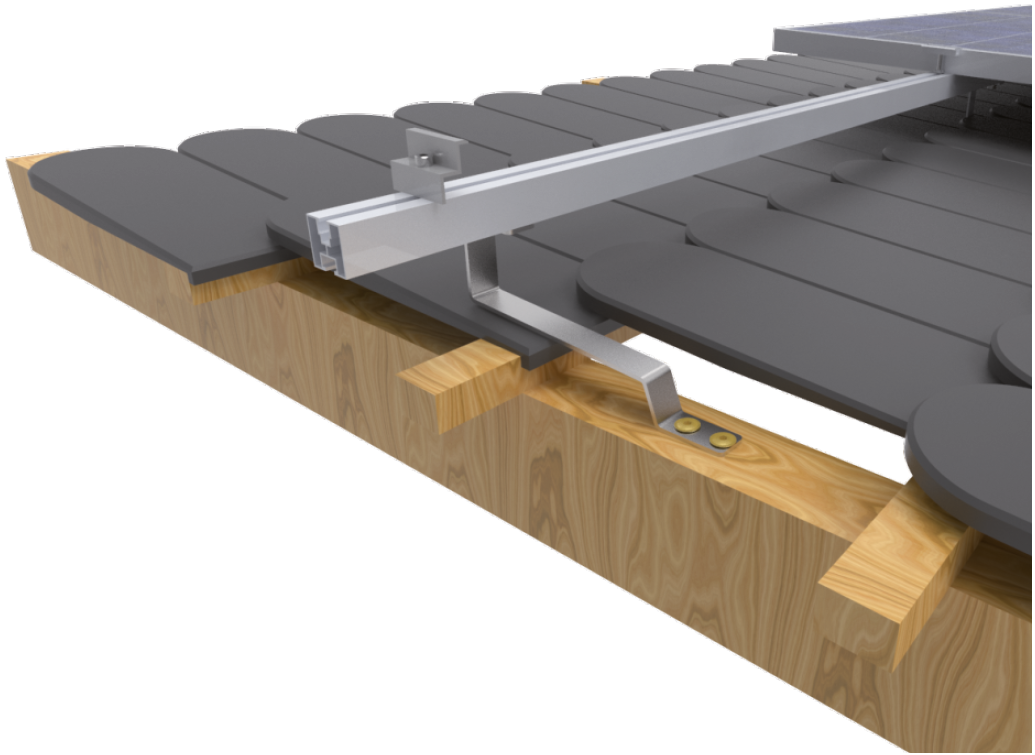

Structure description

Complete support system for any number of PV panels in

a vertical arrangement on a sloping roof covered with

scale-shaped tiles

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Installation of holders with screws for roof rafters.

Recommended spacing between holders 0.8 – 1 m

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– elongated arm of the holder allows the hooks to be mounted

on the majority of ceramic and concrete roof tiles available

on the market

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

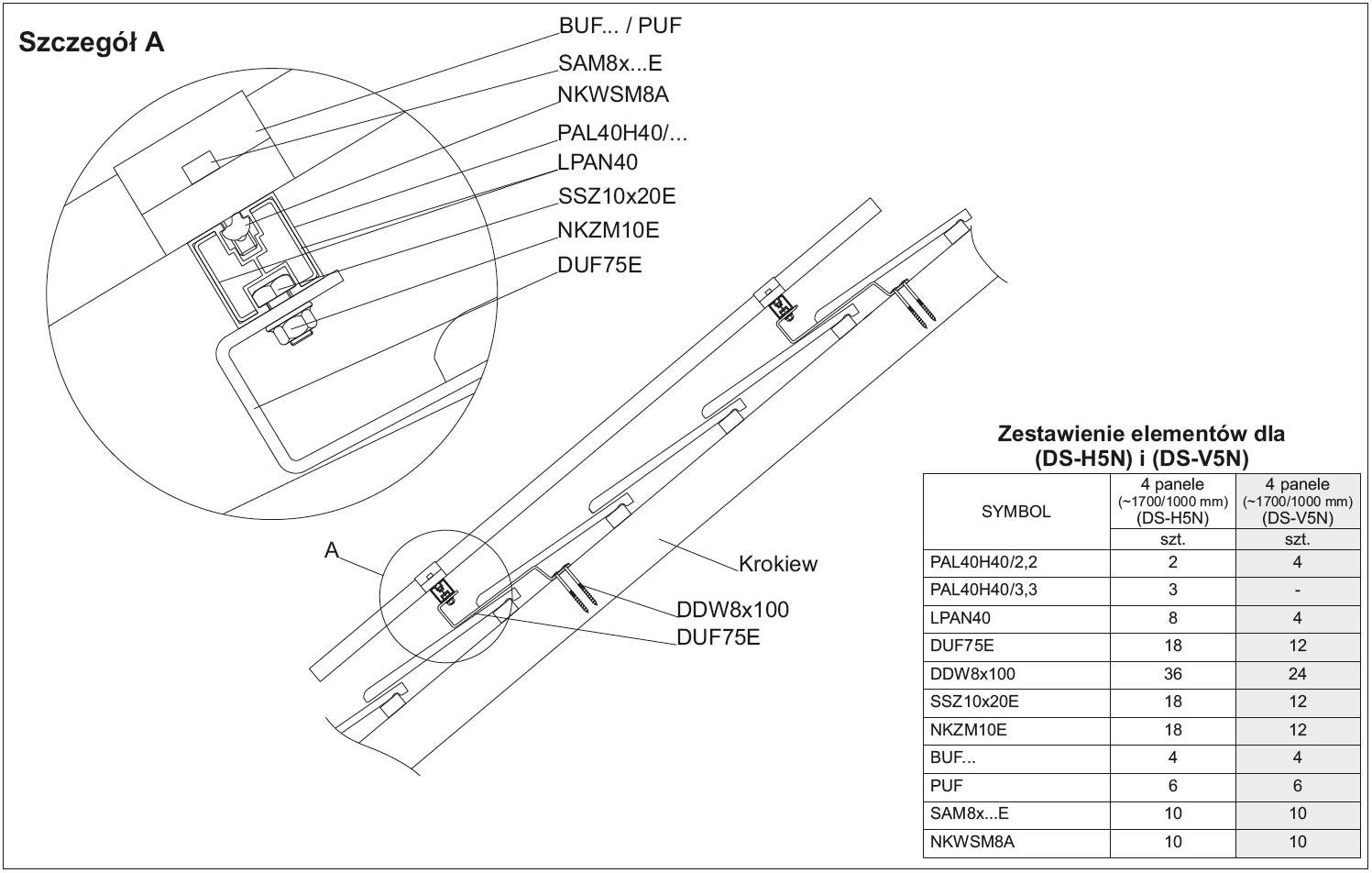

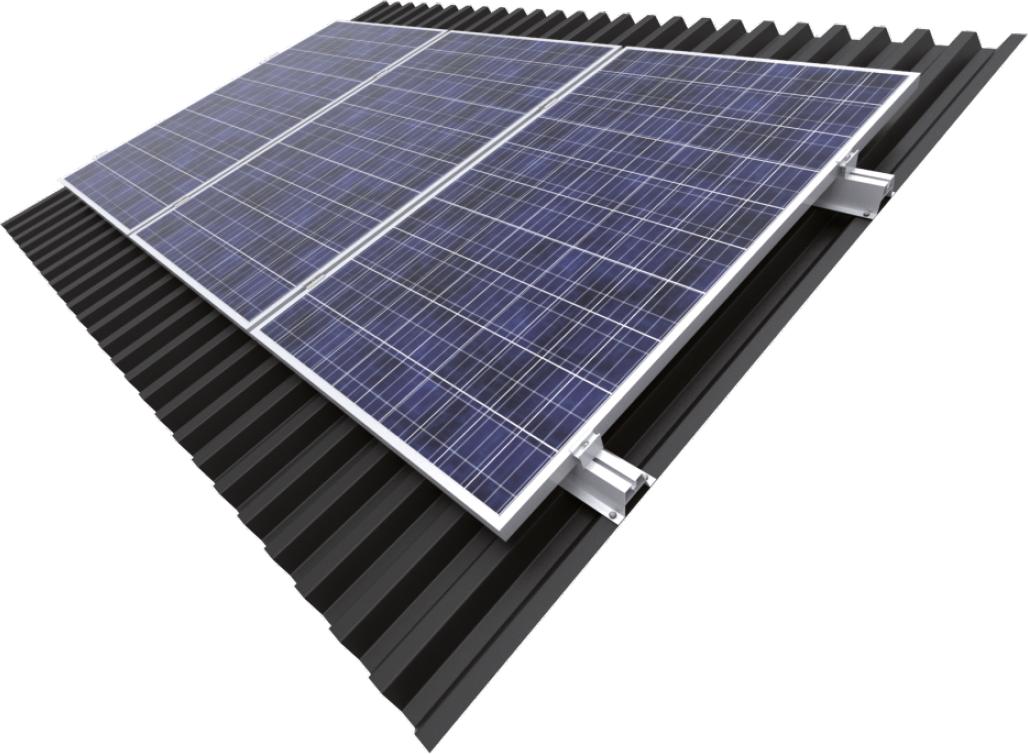

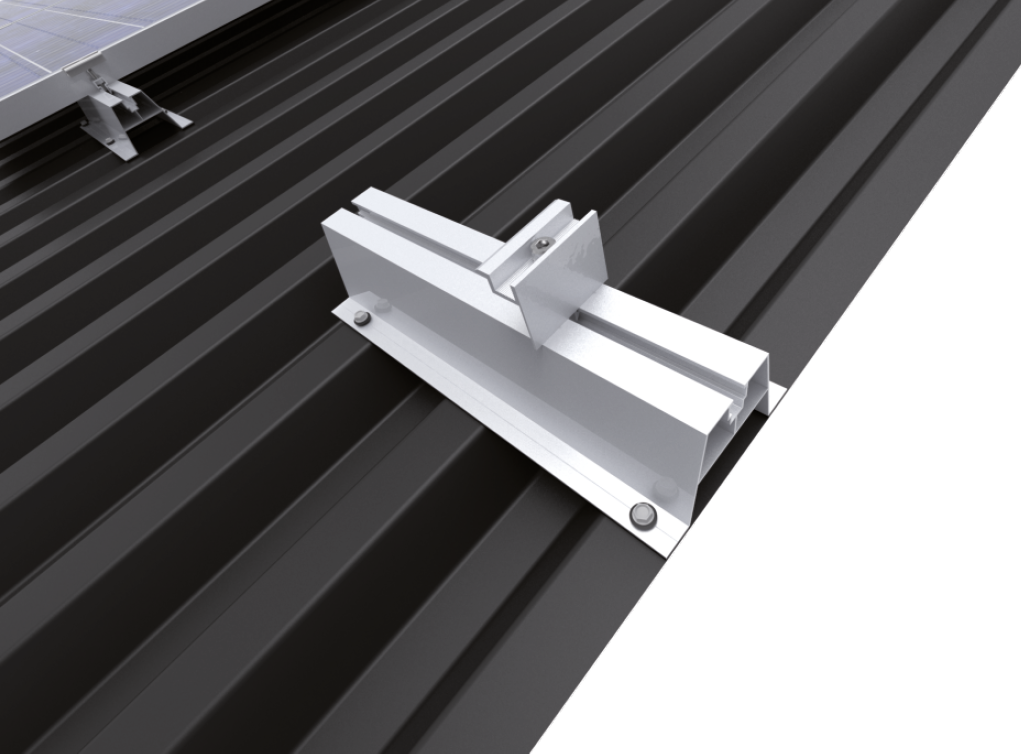

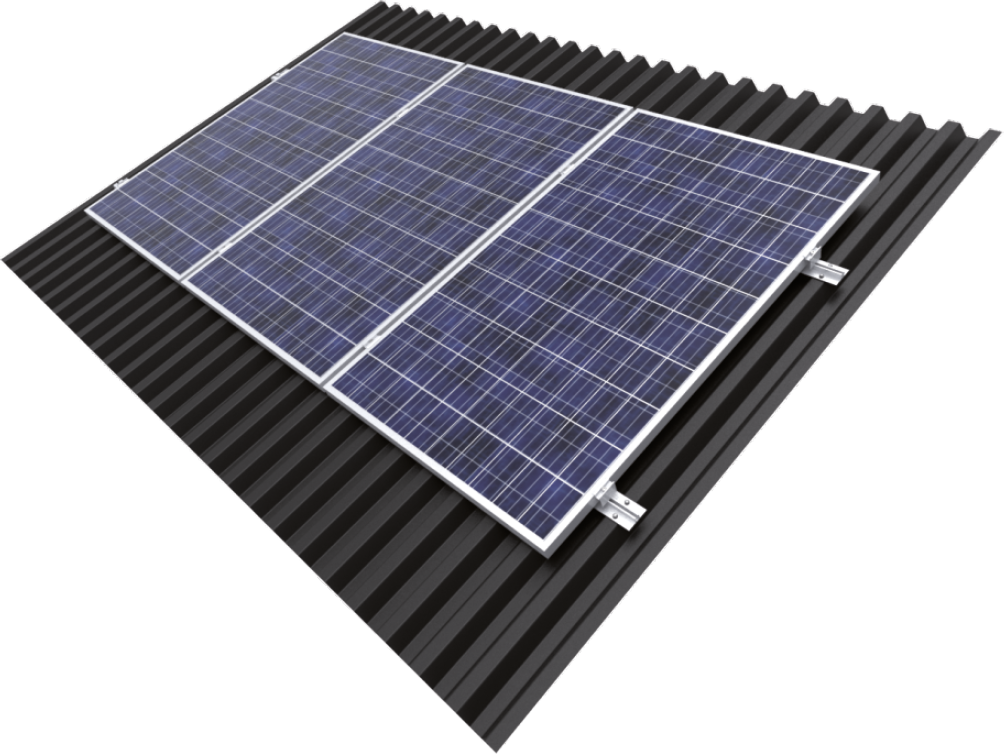

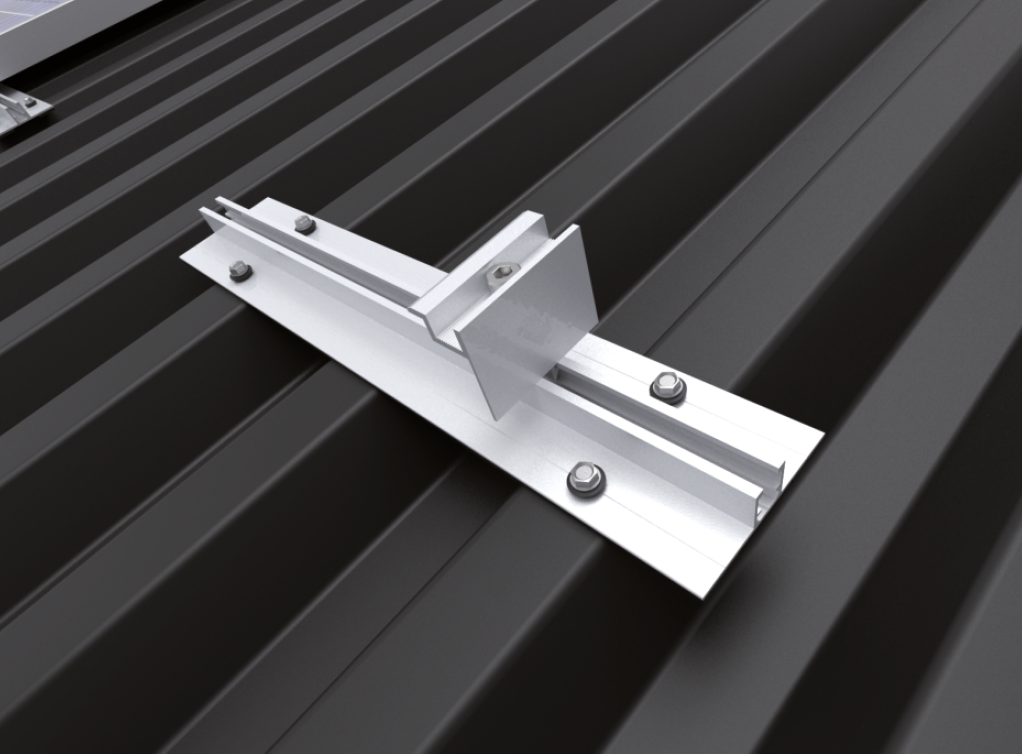

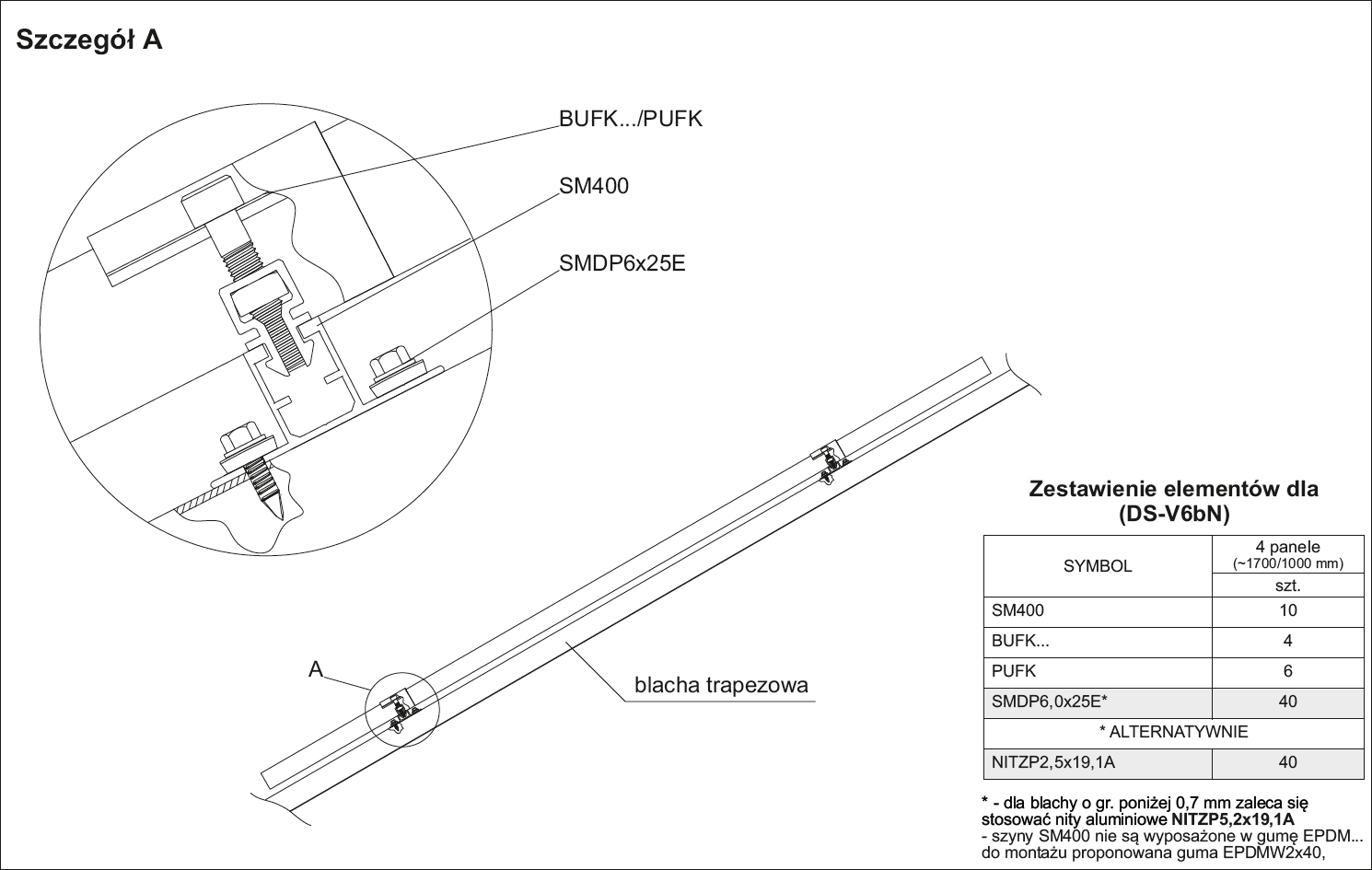

Structure description

Complete support system for any number of PV panels in

a vertical arrangement on a sloping roof covered with

trapezoidal metal sheets

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– quick installation of the structure using threaded screws

directly to the trapezoidal metal sheets without the need

to locate the rafters

– very economical design with a small number of components

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

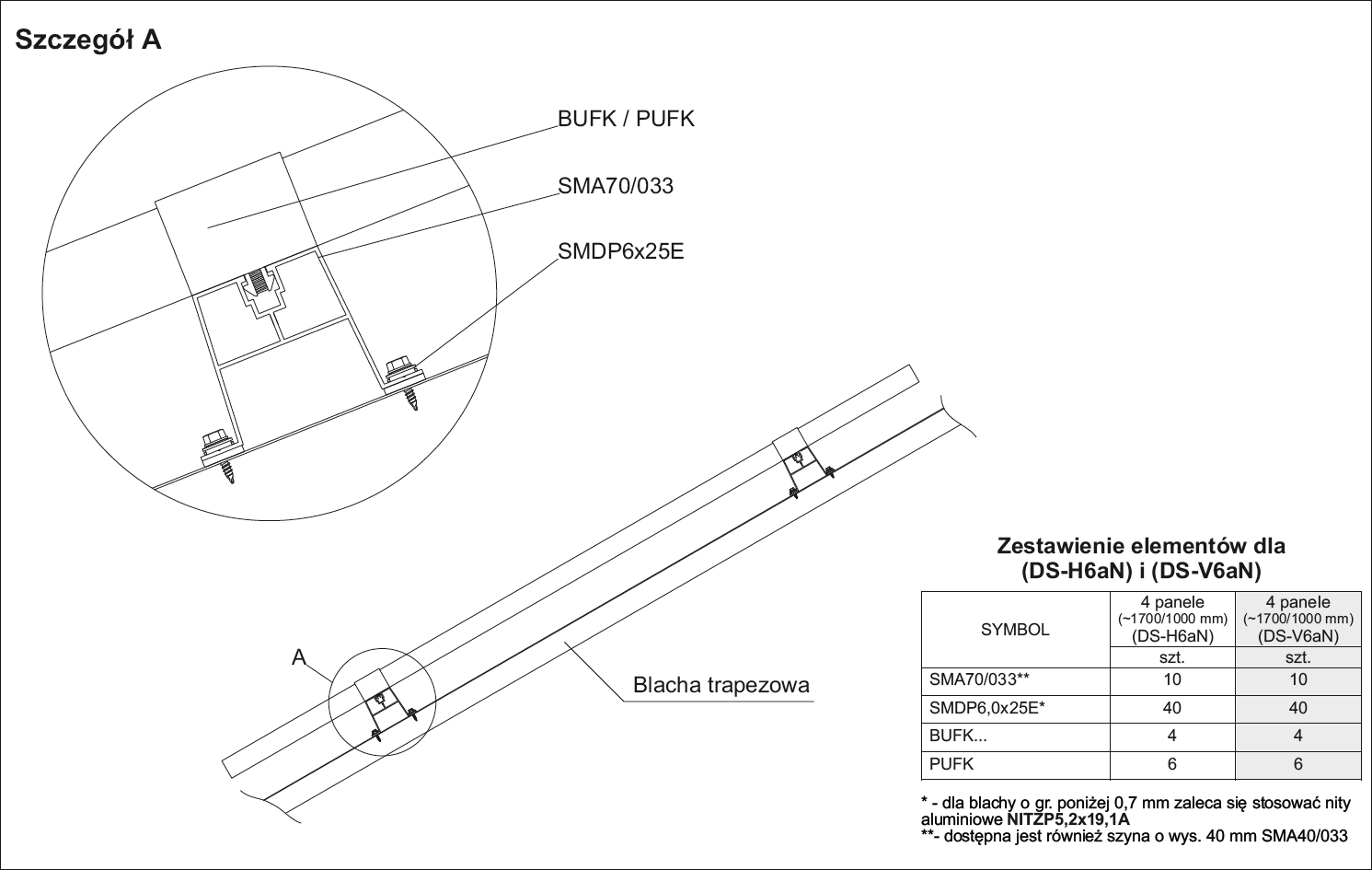

Structure description

Complete support system for any number of PV panels in

a vertical arrangement on a sloping roof covered with

trapezoidal metal sheets

Technical description:

Materials of the support system:

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Arrangement of the modules:

· horizontal – H · vertical – V

Advantages:

– quick installation of the structure using threaded screws

directly to the trapezoidal metal sheets without the need

to locate the rafters

– very economical design with a small number of components

– the elements are made of stainless steel and aluminium,

which guarantees very high corrosion resistance

– high stability of the structure thanks to the aluminium profile

with a specially profiled section

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

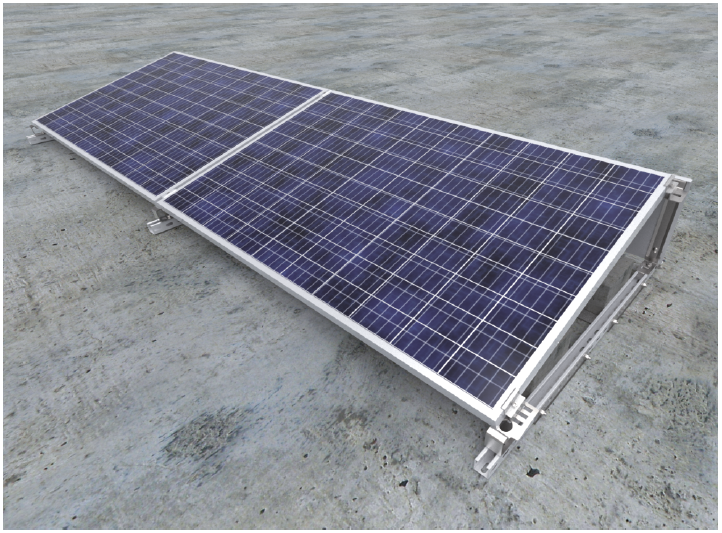

Für Flachdächer

– structures available in steel in Magnelis® coating and aluminium

– universal structures for flat roofs that can be fixed directly to the roof plating or used as ballast structures

– variable adjustment and longitudinal profile perforation allows for trouble-free and quick installation of the structure even in case of unevenness on the roof

– perforation in the wind shields allows for easy and quick installation even after the photovoltaic panels have been installed

– specially designed profile of the wind shields ensures stable adhesion to the structure, and after using additional pressure plates, even strong wind does not cause resonance

– the dimensions of the wind shields are adapted to various types of panels, thanks to which their installation does not require drilling

– triangular structures made of channels allow the panels to be mounted to steel profiles in the Magnelis® coating and aluminium profiles

– products made in Poland!

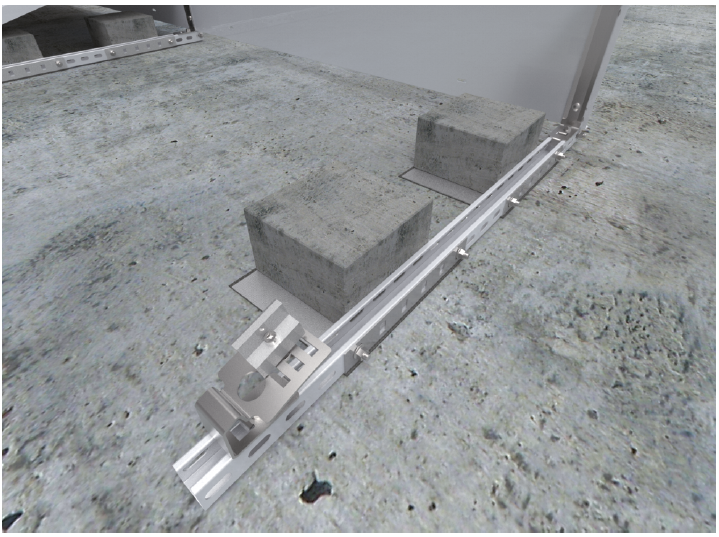

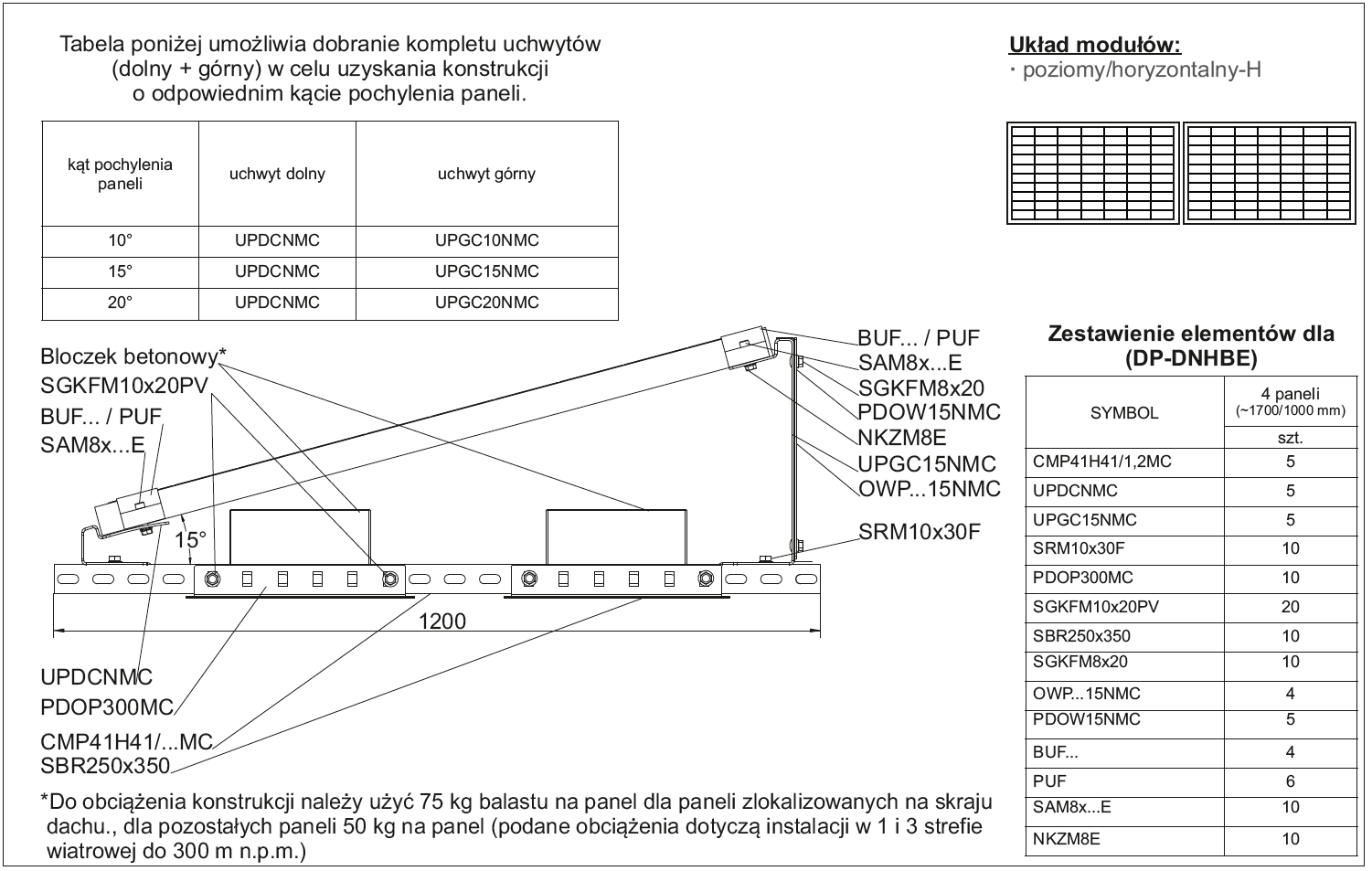

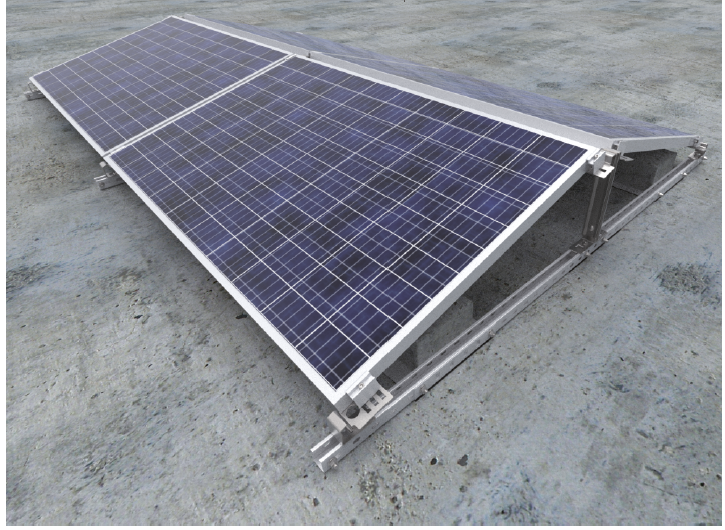

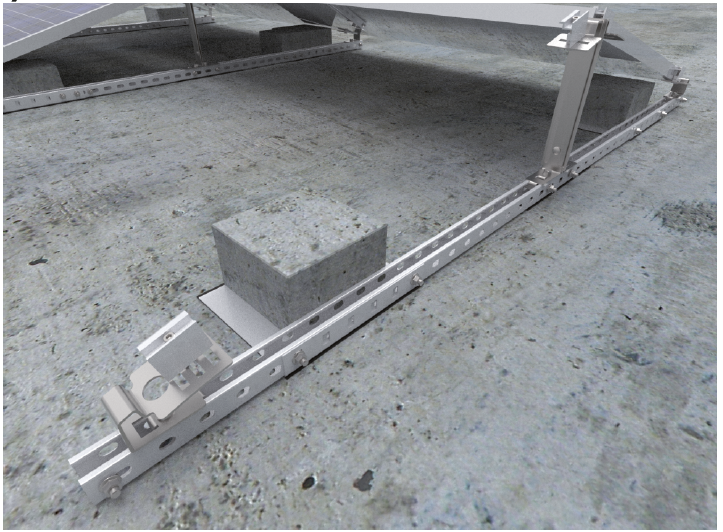

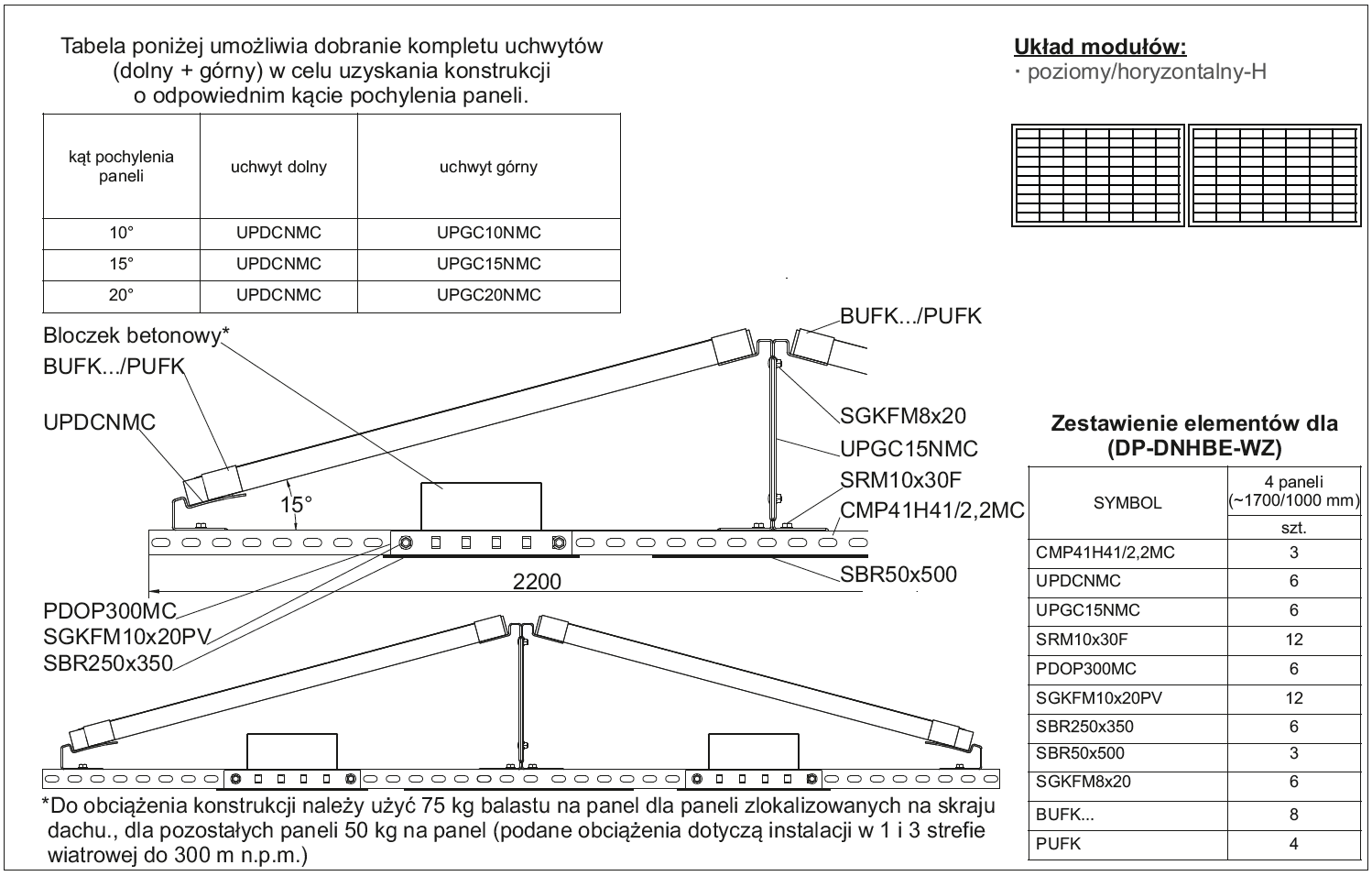

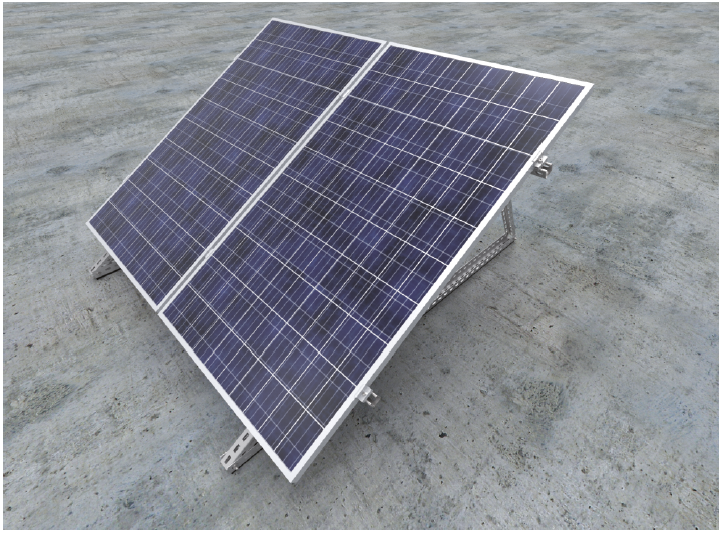

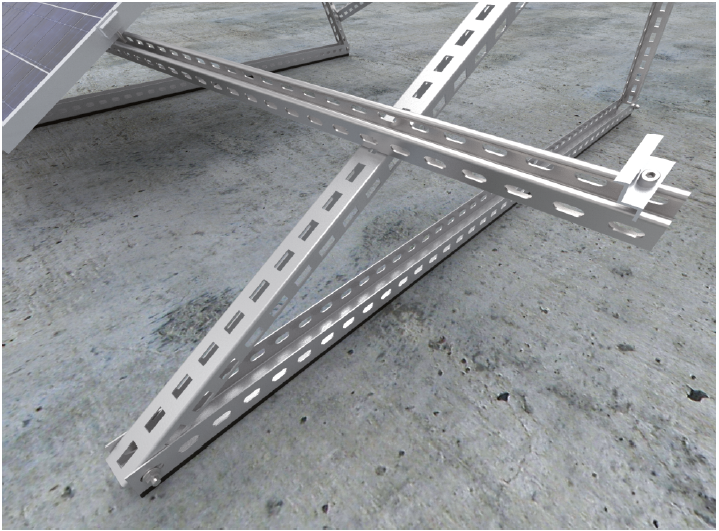

Structure description

Complete support system for fixing the panels horizontally at angles

of 10°, 15° and 20° on a flat roof. The DP-DNHBE system enables

the panels to be installed without disturbing the roof plating thanks

to the ballasting of the structure with concrete blocks (use blocks

made of B20 concrete, and protect them from soaking in rainwater).

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

• anchored to the roof

• ballast (after using sleeper paddings and ballast bases)

Advantages:

– quick installation and low price,

– strength tested structure

– Magnelis®-coated sheet metal structure guarantees very high

corrosion resistance

– fixing the panel holders to the main profile with one screw and

rhomboid nut

– variable adjustment of the spacing of holders in the main

profile

– longitudinal holes for mounting photovoltaic panels with

possibility of adjustment when mounting panel holders

– bottom holder for setting three angles: 10°, 15° and 20°

– possibility of mounting panels with a length of ~ 2 m

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

Structure description

Complete support system for fixing the panels horizontally at angles

of 10°,15° and 20° on a flat roof. The DP-DNHBE (W-Z) system

enables the panels to be installed without disturbing the roof plating

thanks to the ballasting of the structure with concrete blocks (use

blocks made of B20 concrete, and protect them from soaking

in rainwater).

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

• anchored to the roof

• ballast (after using sleeper paddings and ballast bases)

Advantages:

– quick installation and low price,

– strength tested structure

– Magnelis®-coated sheet metal structure guarantees very high

corrosion resistance

– fixing the panel holders to the main profile with one screw and

rhomboid nut

– variable adjustment of the spacing of holders in the main

profile

– longitudinal holes for mounting photovoltaic panels with

possibility of adjustment when mounting panel holders

– bottom holder for setting three angles: 10°, 15° and 20°

– possibility of mounting panels with a length of ~ 2 m

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

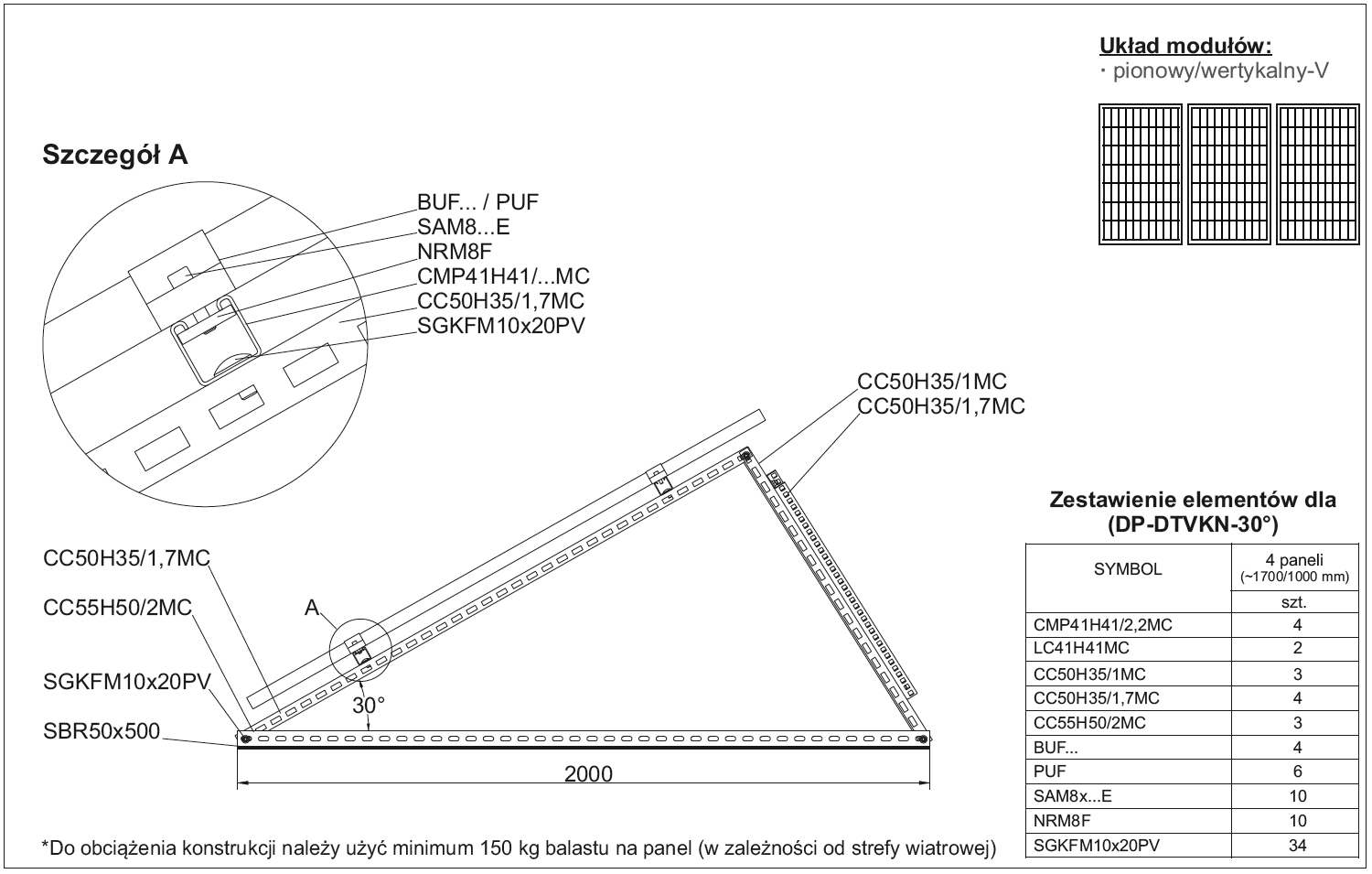

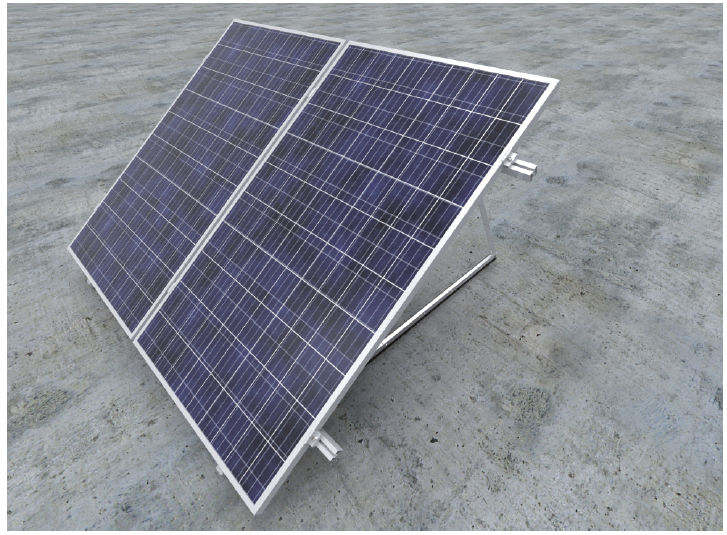

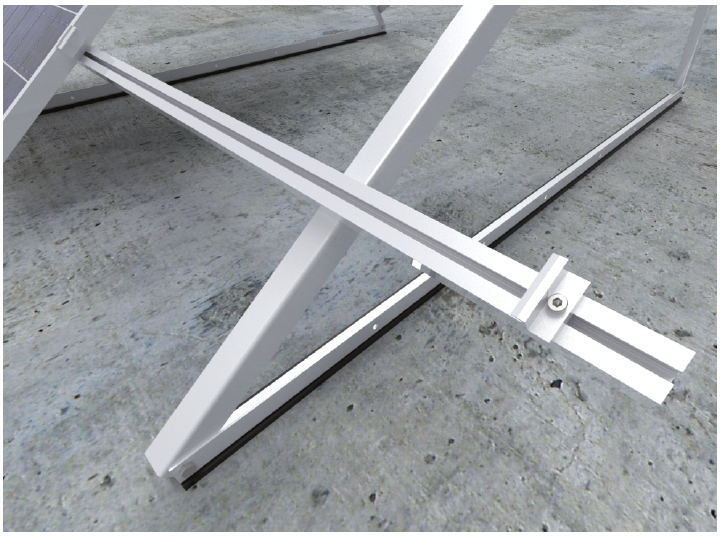

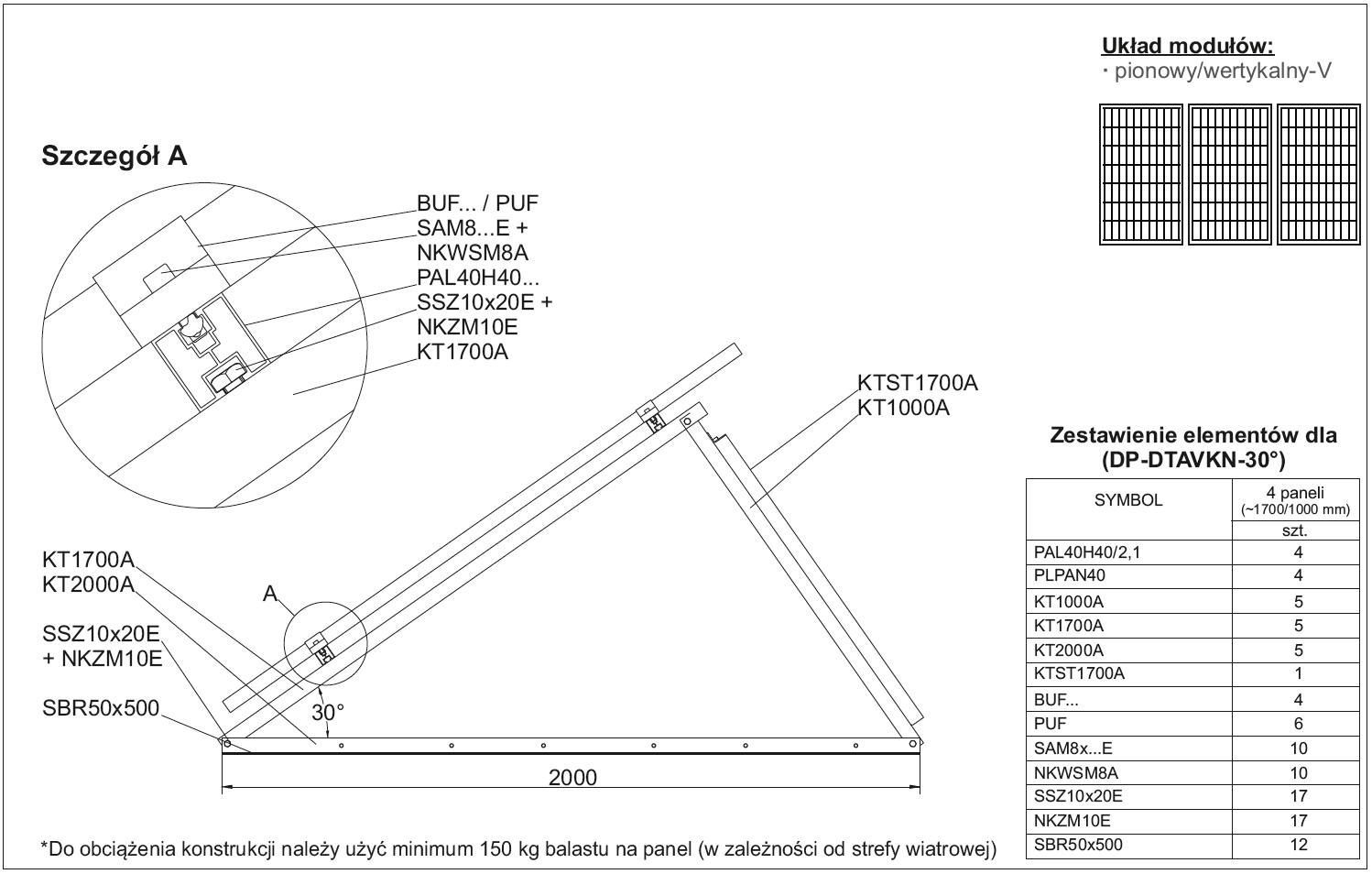

Structure description

Complete support system for fixing the panels vertically

at angles of 25°, 30° and 35° on a flat roof.

Anchored structure.

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

• anchored to the roof

• ballast (after using sleeper paddings and ballast bases)

Advantages:

– quick installation

– low price

– strength tested structure

– high stability of the structure

– Magnelis®-coated sheet metal structure guarantees very high

corrosion resistance

– possibility of fixing the panels on aluminium and steel profiles

in Magnelis® coating

– possibility of setting three angles: 25°, 30° and 35°

– possibility of mounting panels with a length of ~ 2 m

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

Structure description

Complete support system for fixing the panels vertically

at angles of 25°, 30° and 35° on a flat roof.

Anchored structure.

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

• anchored to the roof

• ballast (after using sleeper paddings and ballast bases)

Advantages:

– quick installation

– low price

– strength tested structure

– high stability of the structure

– aluminium structure guarantees very high corrosion

resistance and lowers the weight of the support structure

– possibility of setting three angles: 25°, 30° and 35°

– lightweight constructions, dedicated to roofs with low load

capacity

– possibility of mounting panels with a length of ~ 2 m.

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

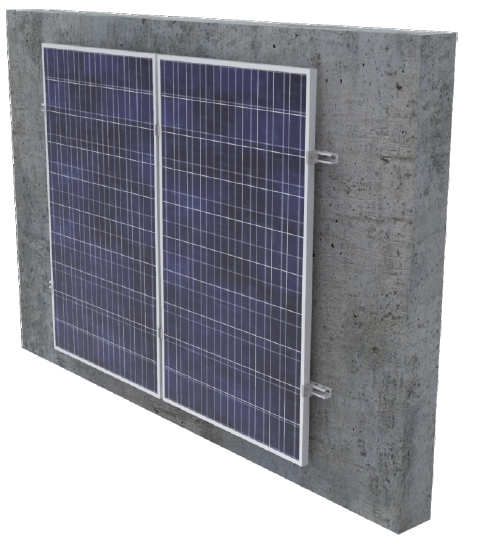

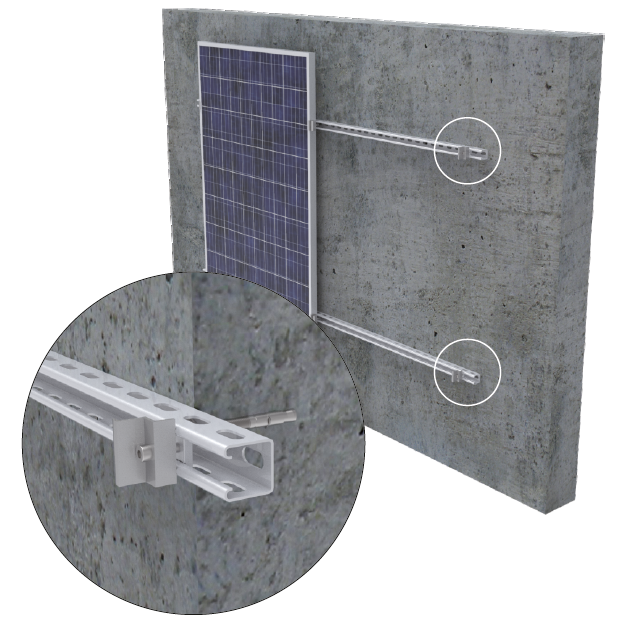

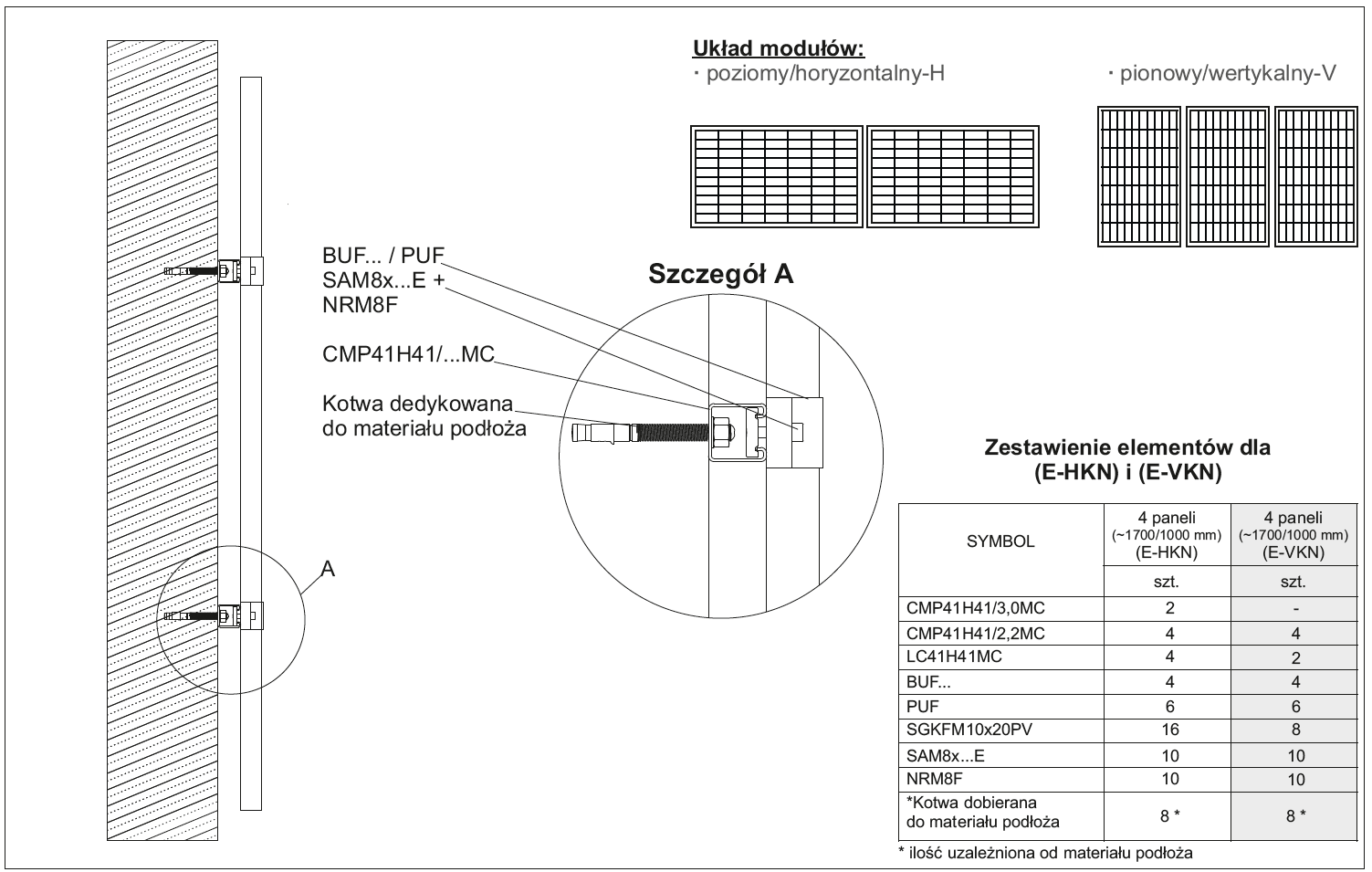

Structure description

Support system for quick installation of PV panels

to building elevations.

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

– Anchored with anchors for concrete

– Anchored with chemical anchors for concrete

– Anchored through with threaded rods (sandwich panel)

Advantages:

– quick installation

– low price

– high stability of the structure

– strength tested structure

– Magnelis®-coated sheet metal structure guarantees very

high corrosion resistance

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

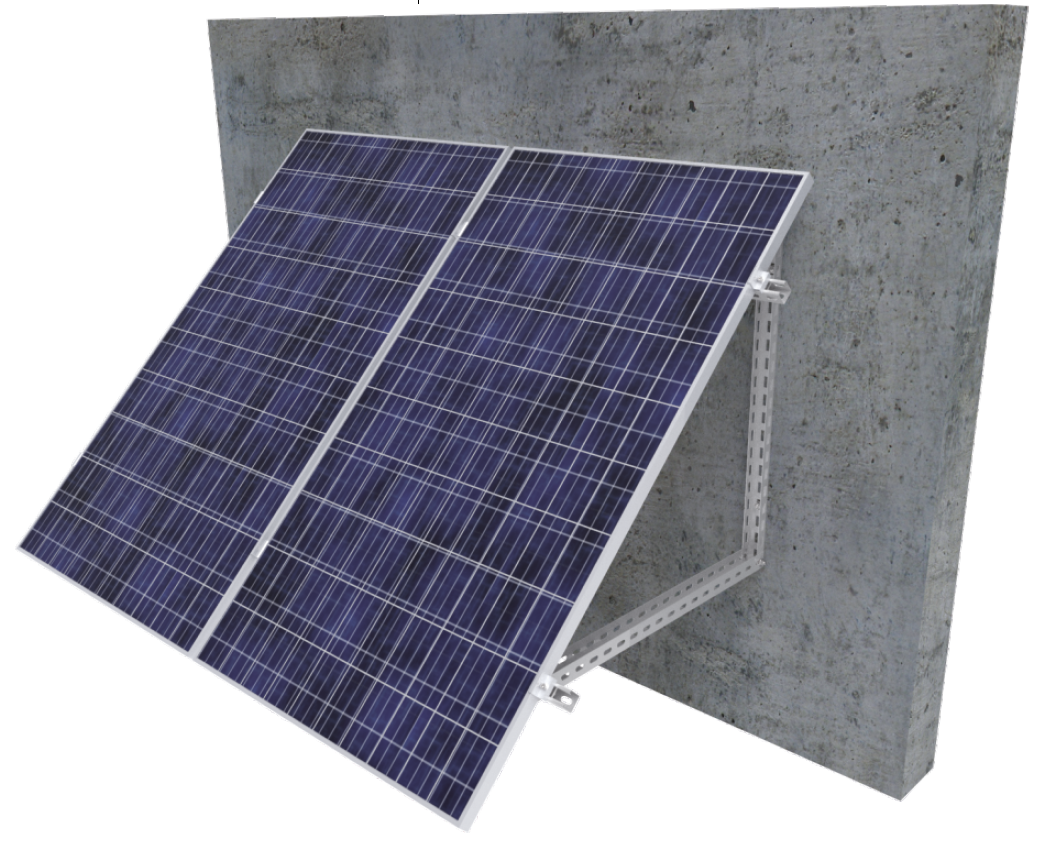

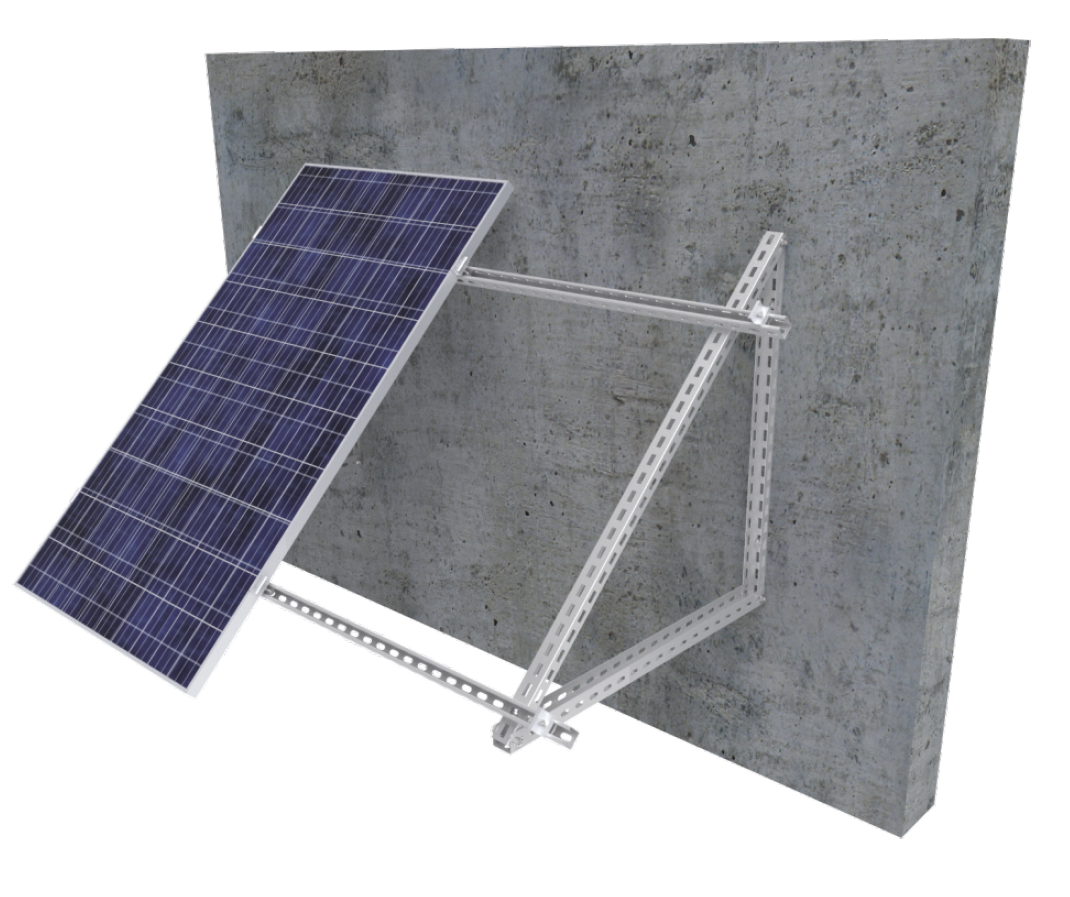

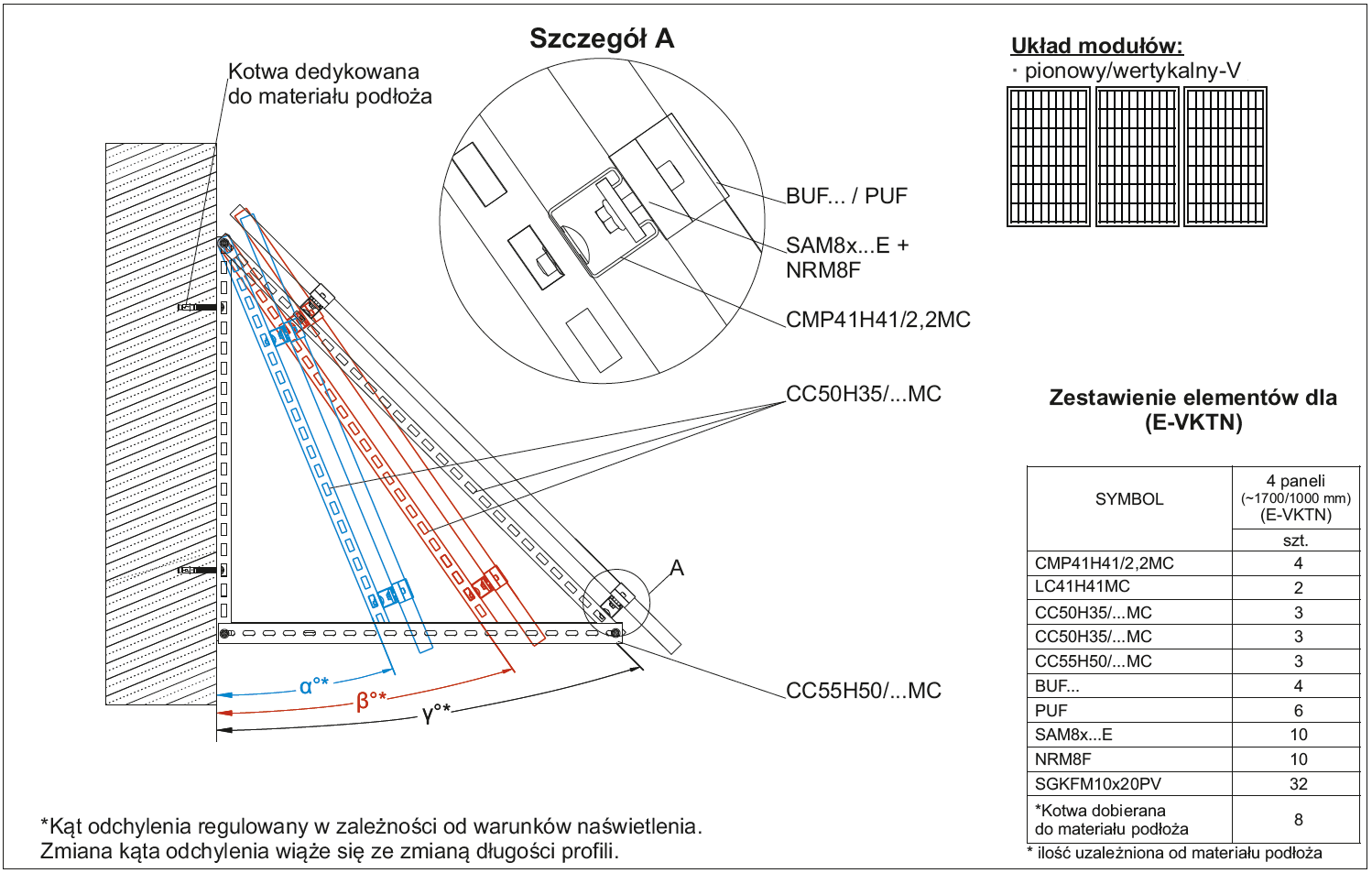

Structure description

Support system for quick installation of PV panels

to building elevations.

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

– Anchored with anchors for concrete

– Anchored with chemical anchors for concrete

– Anchored through with threaded rods (sandwich panel)

Advantages:

– quick installation

– low price

– high stability of the structure

– adjustable inclination angle

– Magnelis®-coated sheet metal structure guarantees very

high corrosion resistance

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met

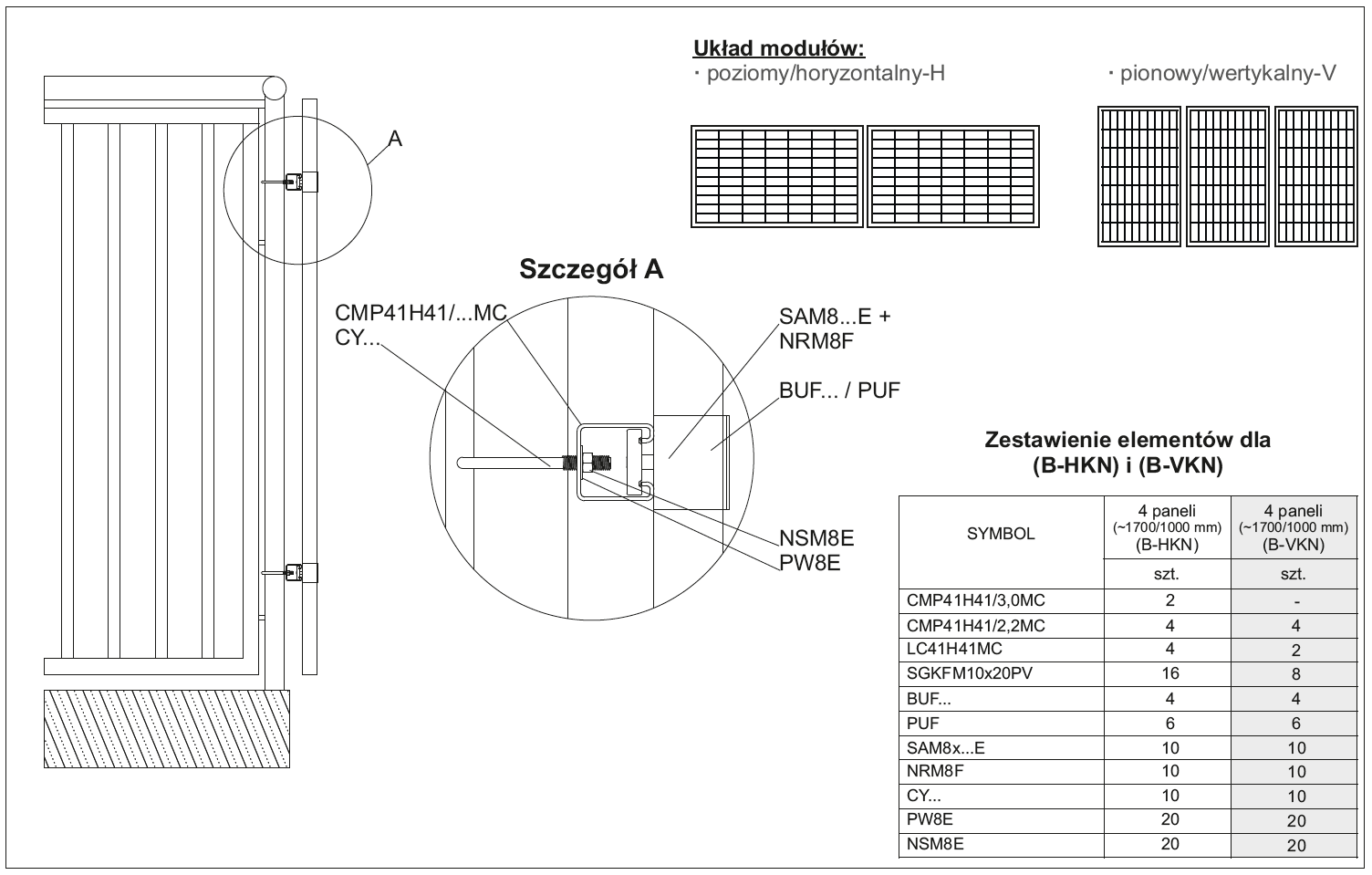

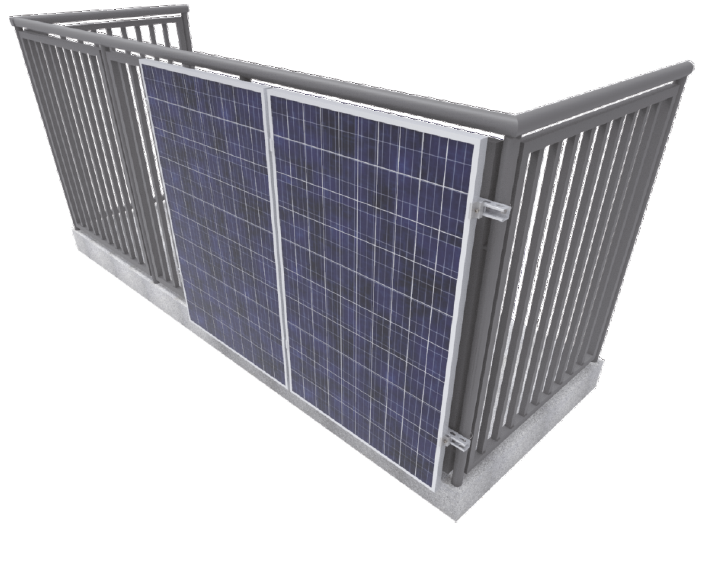

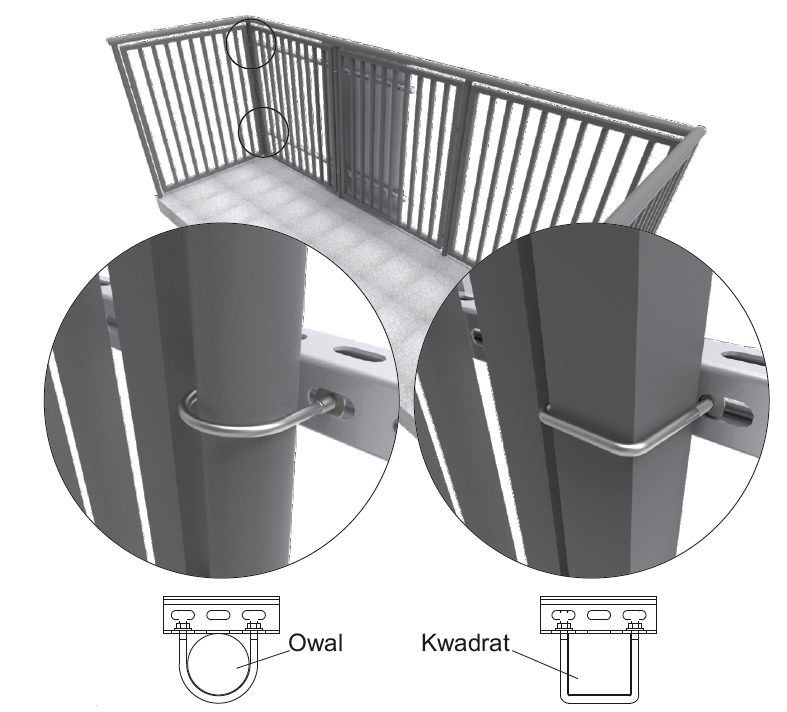

Structure description

Support system for quick installation of PV panels

to balcony railings.

Technical description:

Materials of the support system:

MC- constructional steel in Magnelis® coating or steel, hot-dip galv.

to PN-EN ISO 1461:2011

A- Aluminium

E- Stainless steel

F- Steel in zinc flake coating

Structure tested for strength.

Structure assembly variants:

– screwed to balcony railings of round of

square section with u-bolts

Advantages:

– quick installation

– low price

– high stability of the structure

– strength tested structure

– Magnelis®-coated sheet metal structure guarantees very

high corrosion resistance

Warranty

BAKS provides a 10 year warranty period for the components

included in the support structure only if all conditions of the

manufacturer’s warranty are met